Types of Seamark ZM Electronic Assembly Machines

Zhuomao Technology Co., Ltd has been focusing on intelligent soldering and intelligent inspection equipment for 16 years, and has specialized in providing advanced intelligent BGA Rework Station, X-Ray Inspection Machine, X-Ray Counter Machine, 3D X-Ray Inspection Machine, Automatic Tin Removal Equipment, Automatic Reballing Machine, Laser Soldering Equipment, non-standard automation equipment, and other overall solutions for electronic manufacturing, 3C products, industrial precision castings, semiconductors, and other industries.

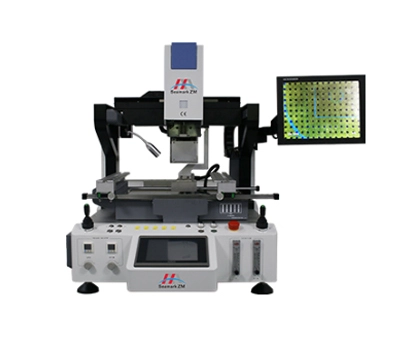

BGA Rework Station

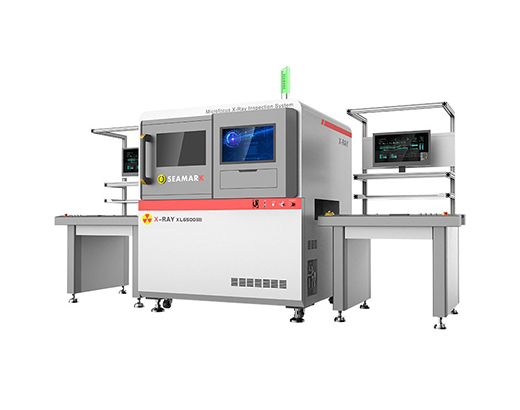

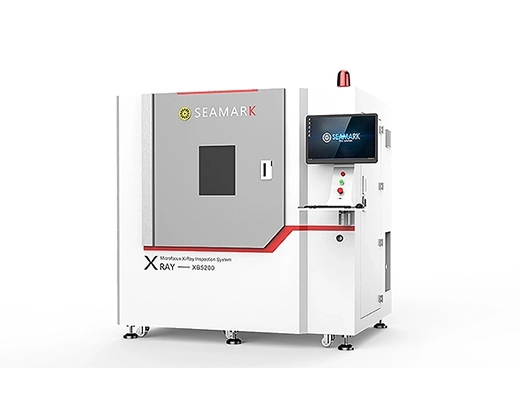

Microfocus X-Ray Inspection Machine

X-Ray SMD Component Counting Equipment

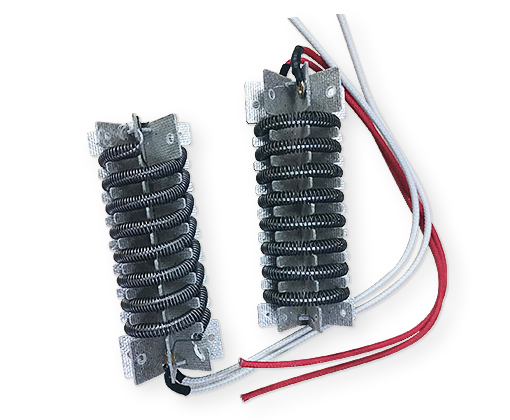

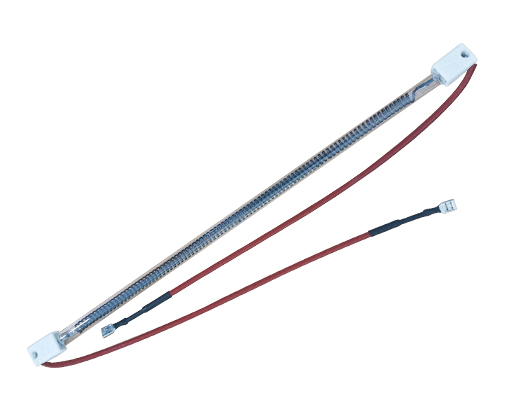

Accessories for BGA Rework Station

Battery X-ray Inspection Machine

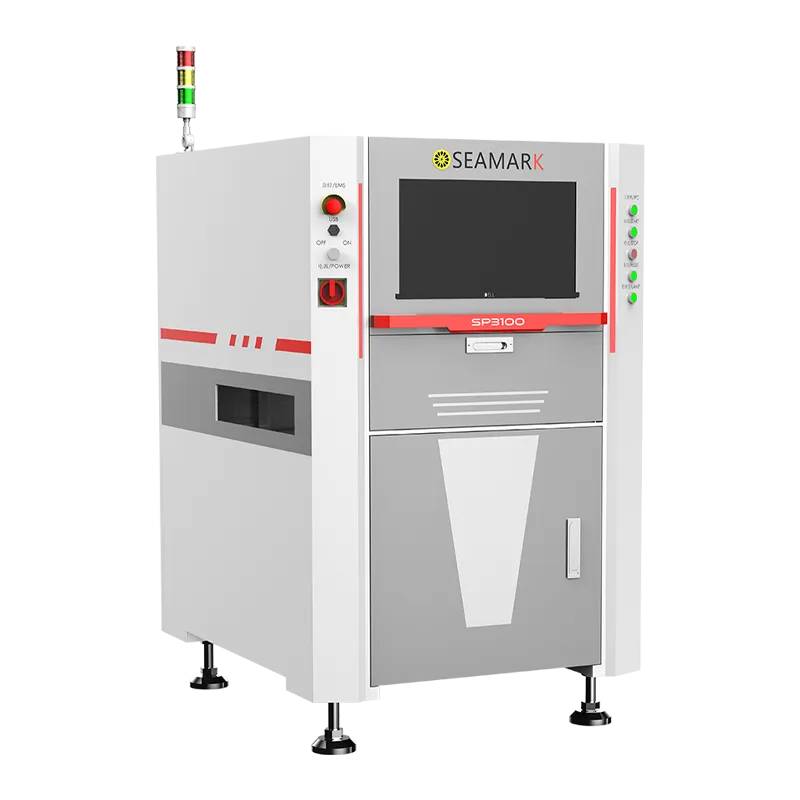

Automated Optical Inspection System

_System.webp)