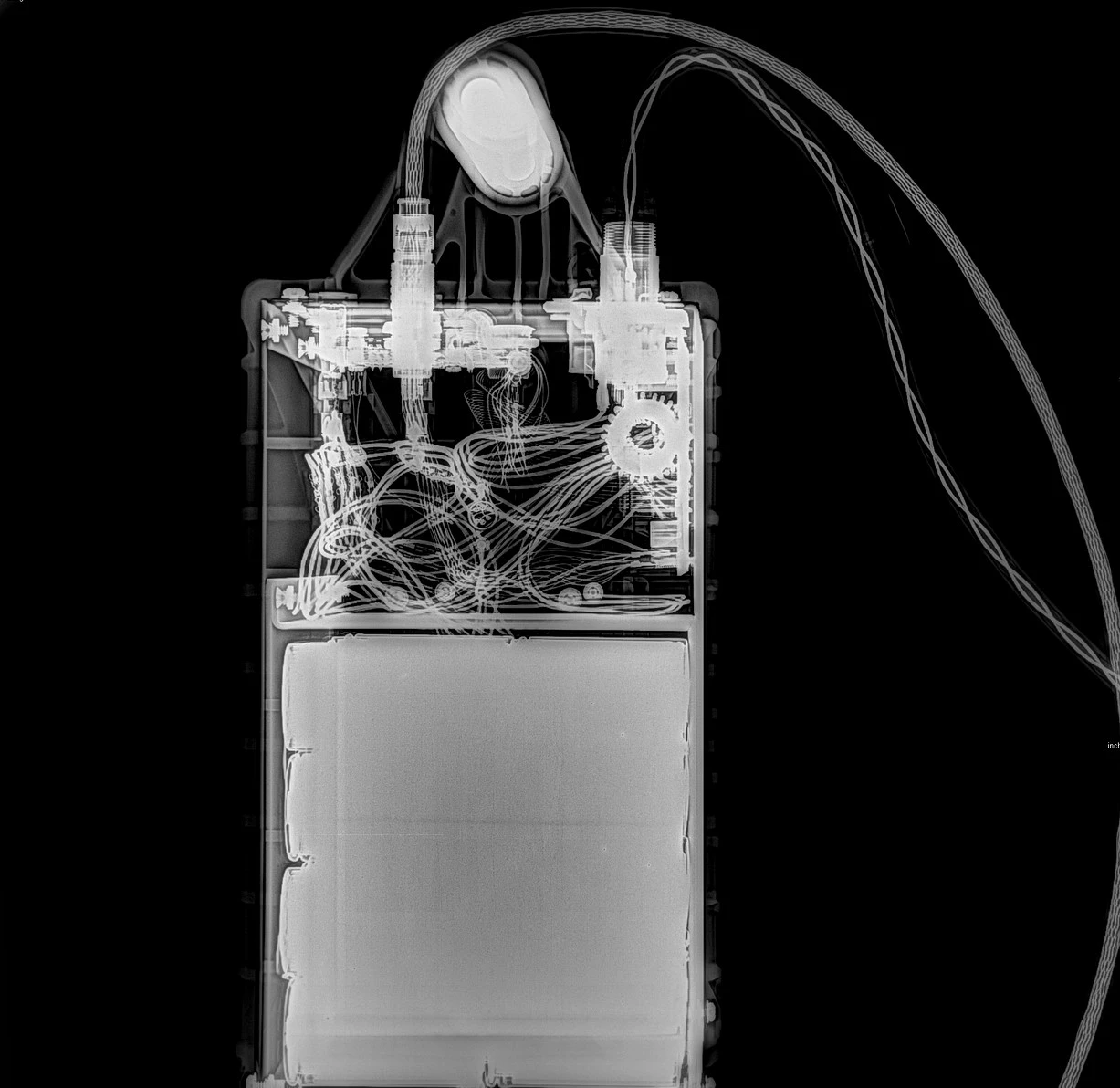

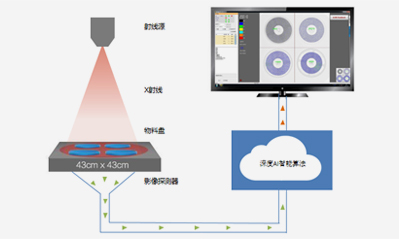

Offline X-ray Inspection Machine uses the penetrating effect of X-ray rays. When X-rays penetrate the objects/material, those objects/material will absorb part of X-rays and the rest X-rays will be received by the detector. Different density objects/materials have different absorbability, which means the detector receives different X-rays after penetrating. It will show the image on display after the detector converts that X-ray into visible light. If you want to know more about the BGA x-ray inspection equipment, please contact Seamark ZM now.

Significance of flaw detection of industrial X-ray machines

Flaw detection is a non-destructive flaw detection method that uses the characteristics of X-ray penetration and attenuation in the material to find the defects. The X-ray can inspect the internal defects of metal and non-metallic materials and their products, such as porosity, slag inclusion, incomplete penetration and other volumetric defects in the weld. Using the method of X-ray radiography, the internal defects of processed parts and welding of materials are displayed from the X-ray film to evaluate the quality of products, so as to judge the advantages and disadvantages of products, improve the production process, improve the product quality and increase the market competitiveness of products.

Application of flaw detection of industrial X-ray machine

The industrial x-ray machine is widely used in flaw detection of auto parts, electronic parts, castings, chemical industry, semiconductors, lithium batteries and other fields.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr