As the market trends for PCB functionality have increased and sizes become smaller, PCBA repair has become highly specialised and demanding.

This has led the manual repairing by hot air guns being difficult, at the same time the success rate is lower. So a suitable rework station machine is essential for the repair of larger and tiny chips. The hot air output of the BGA rework station is uniform, and the heating temperature can be accurately controlled. The temperature difference of the air is controlled within 1 degree. Multi-segment curve heating is used to realize the partial reflow soldering of the PCB rework station to achieve the purpose of repair.

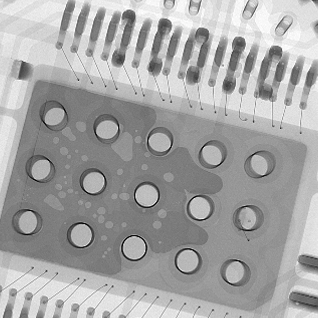

BGA rework stations made by Seamark ZM are equipped with a high-definition alignment system, even tiny chips such as 0.6*0.6mm can accurately be aligned. At the same time, our full automatic visual BGA rework station is suitable for large-size PCBA and IC, such as 5G communication board repair.

Seamark ZM team will provide more and more machines for our clients, not only for general electronic products, but also the advancement products for different kinds of fields.

Rework Station Comparison

| ZM-R5860 | ZM-R7220A | ZM-R730A | ZM-R7830A | ZM-R7850A | ZM-R8650 |

| AC220V±10% 50/60Hz | AC220V±10% 50/60Hz | AC380V±10% 50/60HZ | AC380V±10% 50/60HZ | AC380V±10% 50/60Hz | AC380V±10% 50/60Hz |

| 5.0KW(Max),Top heater(0.8KW) , Bottom heater (1.2KW),IR Preheater (2.7KW), Other(0.3KW) | 5.65KW(Max),Top heater(1.45KW) Bottom heater (1.2KW),IR Preheater (2.7KW), Other(0.3KW) | 7.75KW(Max),Top heater(1.45KW) Bottom heater (1.2KW),IR Preheater (4.8KW), Other(0.3KW) | 7.15KW(Max), Top heater(1.45KW) Bottom heater (1.2KW), IR Preheater (4KW), Other(0.5KW) | 9.85KW(Max),Top heater(1.45KW) Bottom heater (1.2KW),IR Preheater (6.6KW), Other(0.6KW) | 22KW(Max),Top heater(2KW) Bottom heater (2KW),IR Preheater (16KW), Other(2KW) |

| 415×370mm( Max ); 6×6mm(Min) | 412*370mm(Max);6*6mm(Min) | 632*520mm(Max); 6*6mm(Min) | 565*467mm(Max); 6*6mm(Min) | 635*520mm(Max);6*6mm(Min) | 660*600mm(Max);10*10mm(Min) |

| 60×60mm( Max ); 0.6×0.6 mm(Min) | 60*60mm(Max);2*2mm(Min) | 80*80mm(Max); 3*3mm(Min) | 80*80mm(Max); 2*2mm(Min) | 80*80mm(Max);2*2mm(Min) | 100*100mm(Max);1*1mm(Min) |

| 280×380mm | 285*375mm | 570*435mm | 500*380mm | 565*435mm | 640*520mm |

| Y/Z | Z | Z | X/Y/Z | X/Y/Z | X/Y/Z |

| 1 | 1 | 5 | 5 | 5 | 8 |

| 7" HD Touch Screen | 7" HD Touch Screen | 10" HD touch panel (1080P 16:9) | 8" HD touch panel | Computer intelligence operations | Computer intelligence operations |

| Autonomous heating control system V1(software copyright) | Autonomous heating control system V2(software copyright) | Panasonic PLC + Temperature control module | Panasonic PLC + Temperature control module | Industrial PC+ Motion control system | Industrial PC+ Servo motion control system |

| / | 15" SD industrial display (720P front screen) | 15" HD industrial display ( 1080P 16:9) | 15" HD industrial display ( 1080P 16:9) | 15" HD industrial display ( 1080P 16:9)+18.5" SD display | 24" SD display |

| Laser dot | 2 Million Pixel SD digital imaging system, automatic optical zoom with laser red-dot indicator | 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator | 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator | 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator | 2 Million pixels vision alignment |

| / | 50×50mm( Max )Removable camera | 50×50mm( Max )Removable camera | 50×50mm( Max )Removable camera | 50×50mm( Max )Removable camera | 100×100mm( Max ) |

| Manual | Automatic | Automatic | Automatic | Automatic | Full Automatic |

| / | ±0.02mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.025mm |

| K-type thermocouple closed-loop control with accuracy up to ±3℃ | K-type thermocouple closed-loop control with accuracy up to ±3℃ | K-type thermocouple closed-loop control with accuracy up to ±1℃ | K-type thermocouple closed-loop control with accuracy up to ±1℃ | K-type thermocouple closed-loop control with accuracy up to ±1℃ | K-type thermocouple ( closed-loop ), each unit independent temperature control, temperature accuracy up to ±1℃ |

| / | No | Yes | Yes | Yes | Semi-automatic |

| V-groove with universal fixture | V-groove with universal fixture | V-groove with universal fixture | V-groove with universal fixture | V-groove with universal fixture (shaped fixture can be customized) | L shape + universal fixture (shaped fixture can be customized) |

| L635*W620*H655mm | L685*W633*H850mm | L1000*W835*H960mm | L810*W1100*H960mm | L835*W960*H1640mm | L1235*W1215*H1850mm |

| 43.5KG | 76KG | 130.5KG | 151KG | 218.5KG | 660KG |

| PCBA board thickness 0.5-2.5mm, Min Pitch 0.15mm | PCBA board thickness 0.5-2.5mm, Min Pitch 0.15mm | PCBA board thickness 0.5-2.5mm, Min Pitch 0.15mm | PCBA board thickness 0.5-2.5mm, Min Pitch 0.15mm | PCBA board thickness 0.5-2.5mm, Min Pitch 0.15mm | PCBA board thickness 0.5-4mm, Min Pitch 0.15mm |

| No | No | No | Yes | No | Yes |

| No | No | No | Yes | Yes ( 0.6Mpa ) | Yes |

| No | No | No | No | Yes | Yes |

|  |  |  |  |  |

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru