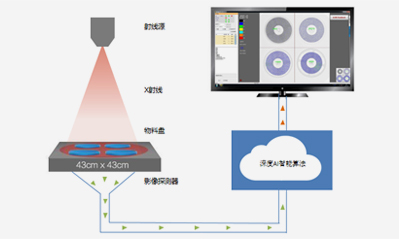

The X-RAY counting machine is based on X-Rays, adopts the principle of photoelectric sensing, and uses the corresponding relationship between the carrier tape guide hole and the components to accurately measure the quantity of SMD components, which can realize convenient and fast counting.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr