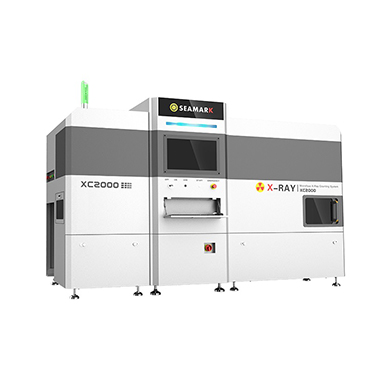

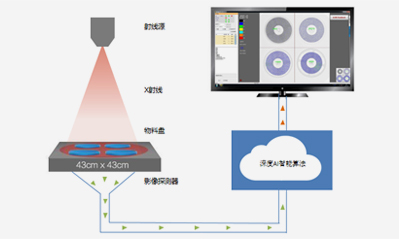

The X-RAY counting machine is based on X-rays, flat-panel imager, and the recognition method of image processing software. It counts the number of graphics representing the original, and then quickly counts reel materials, which is an important machine to realize SMT processing automation.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr