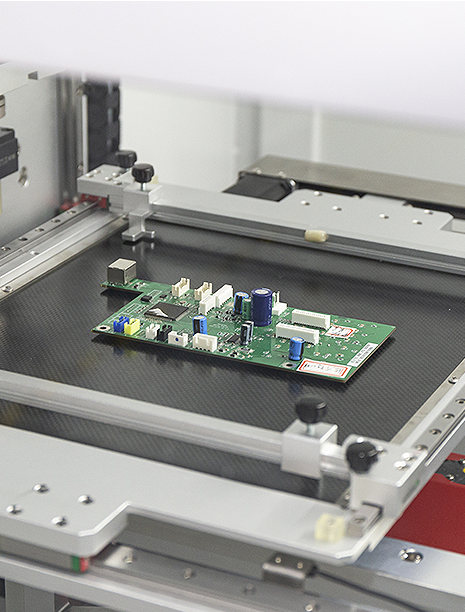

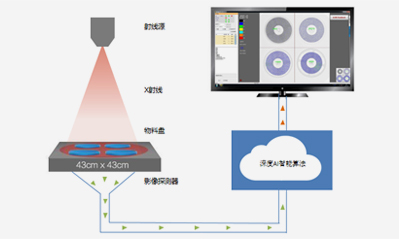

X-Ray SMD Component Counting Equipment

X-Ray SMD Component Counting Equipment

As one of the leading professional BGA reworks machine suppliers in Shenzhen, Guangdong, China, Zhuomao has specialized in research, development, production, and sells superior quality BGA rework stations for more than 10 years.

We insist on the best quality and service to win long-term cooperation with every customer, Our products including BGA machine, x ray inspection machine have passed the ISO 9001: 2000, ROHS, CE, FDA, which makes our processes in line with the best quality practices to ensure better product realization.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru