Break detection equipment adaptation bottleneck, unlock new possibilities for precision testing

In the wave of development in industries such as electronics manufacturing, semiconductors, and new energy, with continuous improvements in product integration and increasingly complex structures, companies have higher demands for the precision and compatibility of detection equipment.

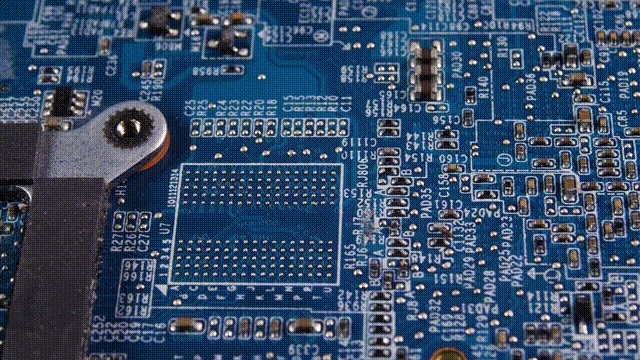

Ultra-large PCBs (such as AI server motherboards, energy control boards, high-density communication boards, etc.) as core interconnect carriers in electronic devices have characteristics of many layers, large size, high wiring density, and stringent electrical performance requirements. Although the application scenarios of ultra-large PCBs vary, they all need to go through the following core process flows: material cutting - inner layer pattern - pressing - drilling - plating - outer layer pattern - solder mask - surface treatment - forming - testing. Each process requires high precision quality control to ensure the final product’s signal integrity, reliability, and yield.

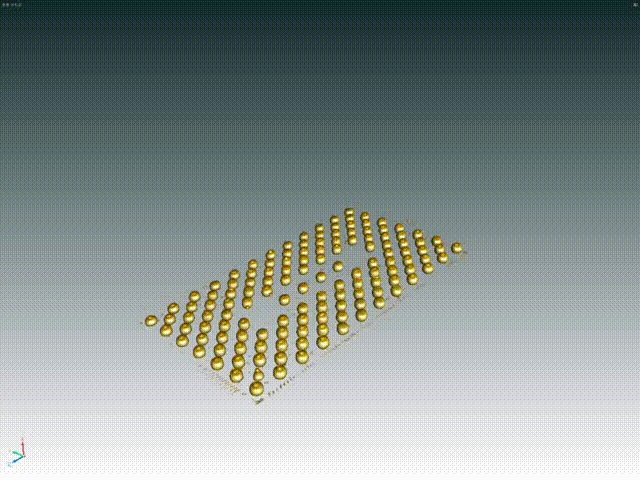

Traditional detection methods face challenges when dealing with ultra-large PCBs, including: conventional 2D X-Ray cannot penetrate multi-layer board structures, cannot resolve multi-layer overlap interference, etc., as well as low detection efficiency, and detection results rely on subjective judgment, unable to achieve full-size three-dimensional intelligent detection; additionally, the detection precision requirements of ultra-large PCBs for interlayer alignment and hole diameter reach micron or even sub-micron levels, making traditional methods difficult to meet technical standards and mass production cycle needs.

Earlier this year, a global leading electronics manufacturing company required PCB sizes for detection far exceeding most detection equipment's compatibility range on the market. They also struggled to find suitable detection solutions for internal wire bundles in metal pipes. Multiple suppliers informed them that they could not meet their customized requirements. When the company faced detection difficulties, SEAMARK's industrial CT/3D X-Ray detection equipment XCT8500 brought them a turning point. We offered an effective customized solution based on their needs, perfectly matching the company's detection requirements.

XCT8500 is an offline industrial CT/3D X-ray detection equipment that adopts the COMET open X-ray tube design, equipped with innovative self-developed intelligent detection software and professional CT analysis and visualization software. It supports 360-degree any-angle detection, with defect detection capabilities smaller than 1μm. It is suitable for quality inspection, three-dimensional measurement, and non-destructive analysis. For the characteristics of microscopic internal structure of samples, combined with qualitative and quantitative analysis software, it realizes multi-angle measurement and analysis of samples, providing effective data for product quality inspection.

"From 'undetectable' to 'complete transparency' quality control leap"

XCT8500 Ultra-Large Customized Solution

Supports 750mm*750mm PCB full board size, comprehensively improving detection efficiency.

Three-dimensional visualization of internal structures, shortening defect analysis and process optimization time.

Reinforced load-bearing platform, supporting a maximum weight of 30kg, ensuring positioning stability.

Detection capabilities: The geometric magnification ratio can reach up to 2500 times, equipped with a 160KV open X-ray source, capable of penetrating materials of different densities.

360° rotation observation mode: 360-degree any-angle detection, supporting multiple imaging modes such as 2D/2.5D/3D.

Data traceability: Barcode information associated with detection results, supporting integration with MES systems, tracing product defects, efficiently statist ical analysis, improving processes, and enhancing product quality.

In today's fiercely competitive industries, the performance and compatibility of detection equipment directly impact a company's core competitiveness. Leveraging high-precision imaging capabilities and flexible customization advantages, SEAMARK is helping more and more companies overcome detection challenges, driving process innovation with precise testing, and gaining an edge in the smart manufacturing race.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru