BGA rework equipment is an essential tool for electronics manufacturers and repair shops. BGA technology, which stands for Ball Grid Array, is a type of surface-mount packaging for integrated circuits. As technology continues to advance, the need for efficient and reliable BGA rework equipment becomes increasingly important. In this blog post, we will explore different types of BGA rework systems and their functions, with a focus on the Seamark brand.

BGA preheaters are used to evenly distribute heat across the circuit board during the removal or installation of BGAs. They ensure the board remains at a stable temperature, preventing warping and damage. Seamark offers a range of BGA preheaters with adjustable temperature controls, making them suitable for various BGA sizes and types.

One popular type of BGA preheater from Seamark is the SP-3000. This preheater features an infrared heating system that evenly heats the circuit board. It also has multiple heating zones, which allows for simultaneous preheating of different BGA components. The adjustable temperature control and user-friendly interface make the SP-3000 a versatile and efficient choice for BGA rework.

BGA rework stations are complete systems designed for the removal and installation of BGA packages. They offer precise temperature control and hot air delivery mechanisms to ensure successful BGA rework. As one of professional BGA rework station manufactures in China, Seamark supplies a range of BGA rework stations tailored to meet the specific needs of electronics manufacturers and repair technicians.

The Seamark SR820 is a high-performance BGA rework station that combines precision, flexibility, and ease of use. It features a powerful hot air system with adjustable temperature and airflow controls. The intuitive interface and programmable profiles allow for efficient and accurate BGA reworking. The SR820 BGA station also includes a built-in vacuum pen, which aids in picking up and placing BGAs with ease and precision.

BGA soldering stations are used for the reflow soldering of BGA components. They offer controlled heating and precise solder placement to ensure reliable connections. Seamark offers a range of BGA reflow station designed for various BGA sizes and BGA types.

The SS-350 is a top-of-the-line BGA soldering station from Seamark. It features a precise temperature control system and a high-performance soldering iron. The SS-350 BGA machine also has a microscope magnifier, which provides an enhanced view of the soldering process, ensuring accuracy and quality. With its advanced features and robust construction, the SS-350 is a trusted choice for BGA soldering.

Various accessories complement BGA rework equipment and enhance the rework process. Seamark is a trusted accessories rework company, offering a range of accessories to support BGA rework, including BGA reballing kits, BGA stencils, and BGA rework fluxes. These BGA rework tools aid in the precise removal, replacement, and reflow of BGAs, ensuring successful rework operations.

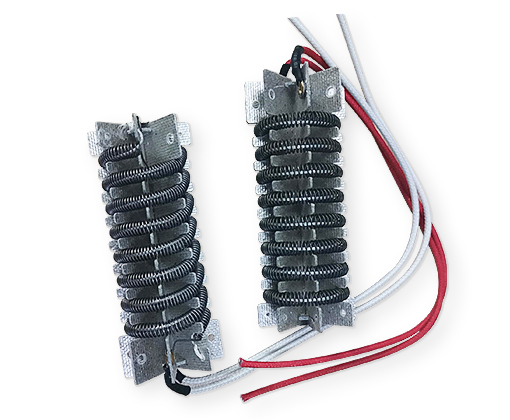

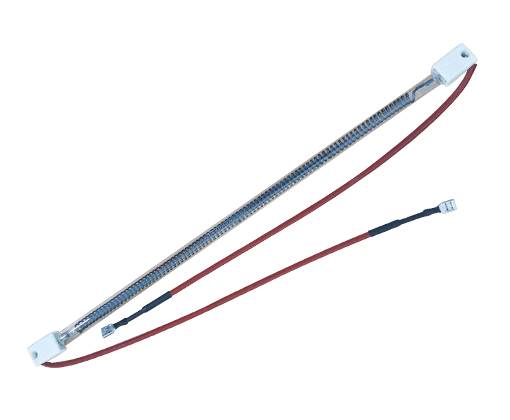

| Top/Bottom Heater | IR Heater for BGA Rework Station |

|  |

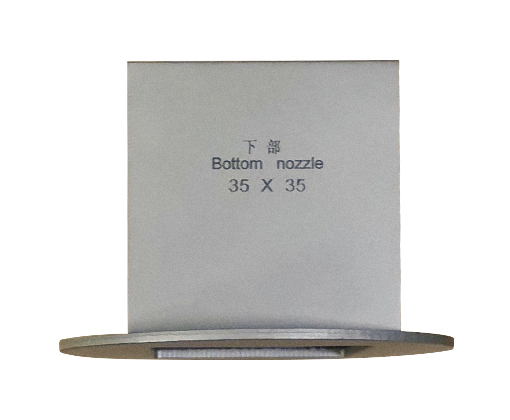

| Top/Bottom Nozzle | Heating Brick (Suitable for ZM-R5830, ZM-R5860 |

|  |

BGA equipment plays a crucial role in the electronics manufacturing and repair industry. Seamark offers a comprehensive range of BGA rework equipment that caters to the specific requirements of professionals in the field. Their BGA preheaters, BGA rework stations, BGA soldering stations, and BGA rework accessories provide reliability, precision, and efficiency for all BGA rework operations. Investing in Seamark BGA rework equipment ensures seamless and successful BGA rework, ultimately enhancing the quality and reliability of electronic devices.

1. What are the benefits of using BGA rework equipment?

Precision and Accuracy

Cost Savings

Versatility across Applications

Controlled Heating

Support for Prototyping and Small-Batch Production

Extended Product Life

2. Why BGA Rework Station is necessary?

Essential for Modern Electronics Repair

Precision in Component Handling

Cost-effective Alternative to Replacement

Ensures Quality and Reliability

3. How to determine the temperature curve of the BGA rework machine?

Understand the Reflow Profile Requirements

Use a Temperature Profiler

Define the Four Main Stages of the Curve

Adjust Machine Parameters

Verify with Trial Runs

Save the Optimized Profile

4. What are some common applications of BGA rework machines?

PCB Repair and Maintenance

Medical Devices

Automotive Electronics

Consumer Electronics Servicing

Telecommunications and Networking Equipment

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru