With the application of high-density packaging technology, the PCBA industry has also brought new challenges to non-destructive technology. In order to cope with new challenges, many technologies are also emerging.

X-RAY inspection equipment is one of the mainstream ways of non-destructive testing equipment. Effectively detect the quality of the X-Ray SMD component counter and PCB assembly. At present, many production industries use X-RAY inspection equipment to better check the internal structure of the product for flaws.

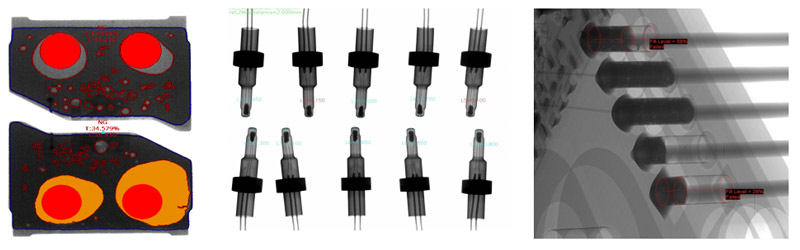

In the PCBA industry, the assembly quality of components is getting more and more attention from EMS companies. In particular, the PCBA package is miniaturized, and the products produced by Seamark are more and more exquisite, which also brings more obstacles to the assembly of the processing personnel. The smaller the PCBA product, the more refined the assembly process and the great operational challenges. In addition, after the Through-hole components are soldered on the PCBA board, the soldering of the components cannot be seen from the appearance due to the pins. Therefore, the X-RAY equipment is used to test the soldering, and the soldering bubbles are observed. Abnormal failure of virtual welding, leakage welding, etc. In a sense, X-RAY detection technology is a necessary means to ensure the quality of electronic assembly.

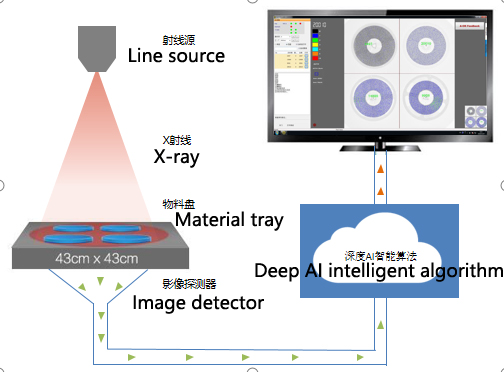

The X-RAY inspection system uses the X-ray emission source as the base point. The X-rays emitted by the high-voltage electrons striking the metal target penetrate the sample, and the detector absorbs and transmits the transmitted light to the display. Therefore, the technician can view the real-time X-ray image of the PCBA directly and start a failure analysis.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru