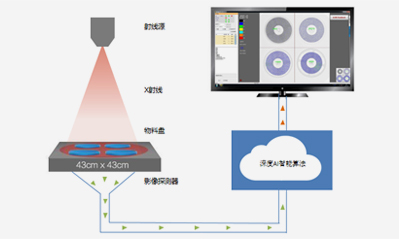

Seamark offers three types of inline-winding battery x-ray inspection machines: the XB7100, XB7300, and XB8100. These automated X-ray inspection machines are commonly used for inspecting various types of winding batteries. For instance, the XB7100 is designed for fully automatic inline inspection of multi-layer winding power batteries. It checks the alignment of positive and negative electrode plates, large surface folds, tab pulling pins, and other aspects of winding power and energy storage batteries. The XB8100 is suitable for cylindrical batteries with diameters ranging from φ14 to φ46mm. To cater to the inspection needs of multi-layer high efficiency under varying diameters, it uses either area array sampling technology or TDI line scanning sampling technology. The inspection parameters include angle overhang, resistance value, conductivity, and more.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr