ZM-R5860 Hot Air BGA Rework Station is a kind of rework station provided by Zhuomao, which has three temperature zone Independently control, convection hot air heating, lower temperature zone height-adjustable, high-precision autonomous control system, high-precision K-type thermocouple with accuracy up to ± 3 ℃, dynamic APR multi-loop closed-loop control selective reflow process. Imported high power constant current integrated cooling fan.

As one of the most reputable BGA Rework Station suppliers, Seamark ZM provides the best BGA Rework Station with good quality. If you want to know seamark ZM R5860 price, please contact us now!

High-definition touch screen operation, real-time display and, editing of temperature curves, each group of temperature curves can be set to 8 segments, 100 groups of temperature curves can be stored, with temperature self-organizing function.

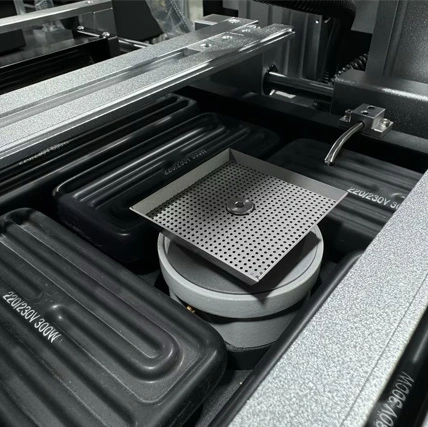

Laser indicator for PCB and component positioning.

The external vacuum suction pen is convenient for taking BGA.

| Power Supply | AC220V±10% 50/60HZ |

| Power | 5.0KW(Max),Top heater(0.8KW) Bottom heater (1.2KW),IR Preheater (2.7KW),Other(0.3KW) |

| PCB Size | 410*370mm(Max); 10*10mm(Min) |

| BGA Chip Size | 40*40mm(Max); 10*10mm(Min) |

| IR Heater Size | 375*285mm |

| Temperature Sensor | 1 pcs |

| Operation Method | 7" HD touch screen |

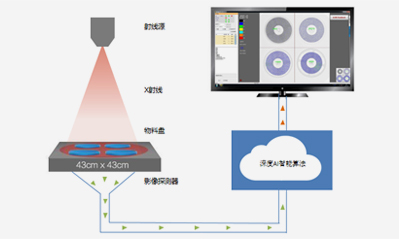

| Control System | Autonomous heating control system V1(software copyright) |

| Alignment System | Laser dot |

| Vacuum Adsorption | Manual |

| Temperature Control | K-type thermocouple closed-loop control with accuracy up to ±3℃ |

| Positioning | V-groove with universal fixture |

| Dimensions | L635*W620*H655mm |

| Weight | 43.5KG |

The Seamark ZM R5860 BGA Machine is a rework station used for soldering and desoldering ball grid array (BGA) components on printed circuit boards(PCBs).BGA components are a type of surface-mount packaging used for integrated circuits.

Seamark ZM R5860 BGA Machine is based on the hot air rework technique. lt uses precisely controlled hot air to melt the solderballs of the BGA component allowing it to be removed or replaced without damaging the PCB or the component itself. The machine also uses a vision alignment system to accurately align the BGA component with the PCB.

The Seamark ZM R5860 BGA Machine allows for precise control over the temperature and airflow, ensuring a reliable and high-quality soldering/desoldering process. lt is suitable for use with a wide range of BGA components and PCBs.

The operation mode of the Seamark ZMR5860 BGA Work Station involves several steps:

Preheating:

The PCB is preheated to a suitable temperature to prevent thermal shock to the board when the hot air is applied.

Alignment:

The BGA component is accurately aligned with the PCB using the machine's vision alignment system.

Soldering/Desoldering:

Hot air is applied to the BGA component to melt the solder balls. For desoldering, the component can then be removed. For soldering. the component is placed on the PCB and the solder is allowed to cool and solidify , creating a strong electrical and mechanical connection.

Cooling:

The PCB is cooled down to room temperature in a controlled manner to prevent thermal stress and warping.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr