R8000D PCB Large Precision Rework Station is an ultra-large high-end optical alignment precision rework station. This BGA workstation is suitable for rework of 5G servers and large server mainboards.

The whole machine produced by Seamark is fully ESD protected, and complies with ESD protection standards.

The safety design of the whole machine complies with the safety design specifications of GB/T15706-2012, and the relevant safety design requirements of GB/T19671 bimanual installation.

The heating area is independently temperature-controlled, and the process temperature can be designed according to the requirements, effectively avoiding PCBA deformation caused by uneven temperature, dual-protecting the heating power devices, and preventing the damage maintenance products caused by temperature's out of control.

With drawer loading design, the stage can be stretched out, which is convenient for picking and placing the maintenance substrate.

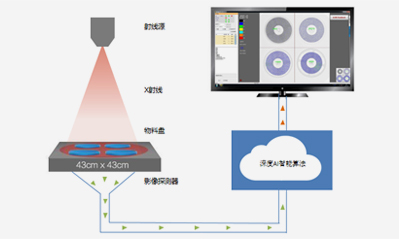

Using self-innovated image alignment technology can effectively solve the problem of visual alignment placement of large-size objects.

The self-developed multi-function foolproof operating system is easy to operate and can be connected with MES/SAP.

Equipped with a high-power silent smoke extraction system, the flux volatile gas generated during the PCBA rework process can be extracted and discharged in time.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable product quality, full service. If you want to know some different types of automatic BGA repair machines and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

| Power Supply | AC380V±10% 50/60HZ |

| Total Power | 33.8KW Max |

| Power | Upper temperature zone(2KW) Lower temperature zone(2KW) Other power(1.8KW) Preheating temperature zone(28KW) |

| Control System | Industrial PC+Servo motion control system |

| Alignment Accuracy | ±0.025mm(X,Y-axis) |

| Temperature Control | K-type thermocouple closed-loop control with accuracy up to ±1℃ |

| Heating Method | Top heating+Bottom heating+Mobile IR heating |

| Temperature Sensor | 6 Pcs |

| Positioning | L-groove with universal fixture(shaped fixture can be customized) |

| PCB Size | 850*660mm(Max); 50*50mm(Min) |

| Temperature control | Full closed-loop control, temperature overshoot/fluctuation does not exceed 5℃, can automatically monitor the heating working status |

| Cooling | Cool wind |

| Cooling Rate | Rapid cooling,200-100℃ single-board cooling rate 0.8~1℃/s |

| Mounting Pressure | <5N |

| Dimensions | L1671*W1771*H1928mm |

| Weight | 929KG |

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr