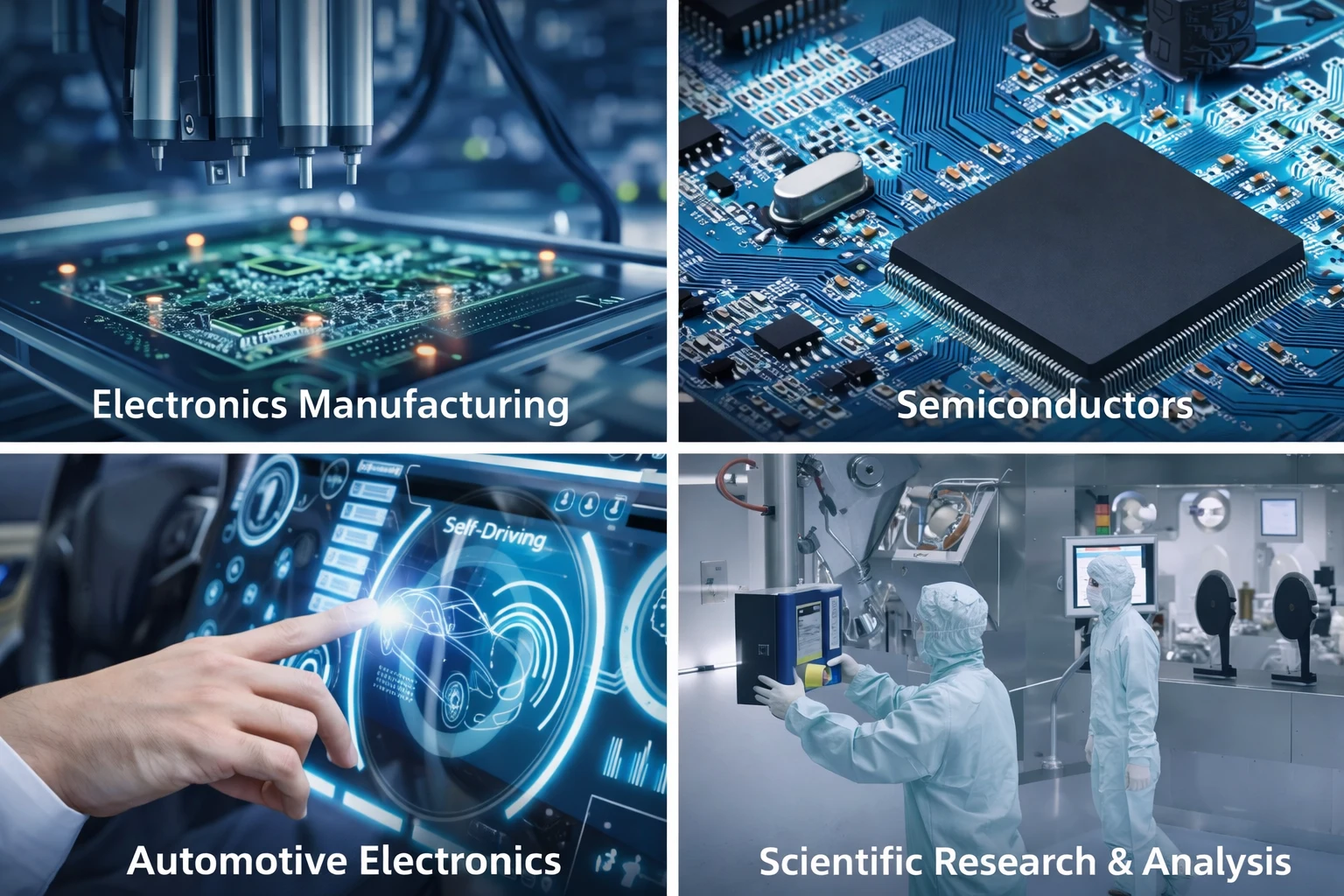

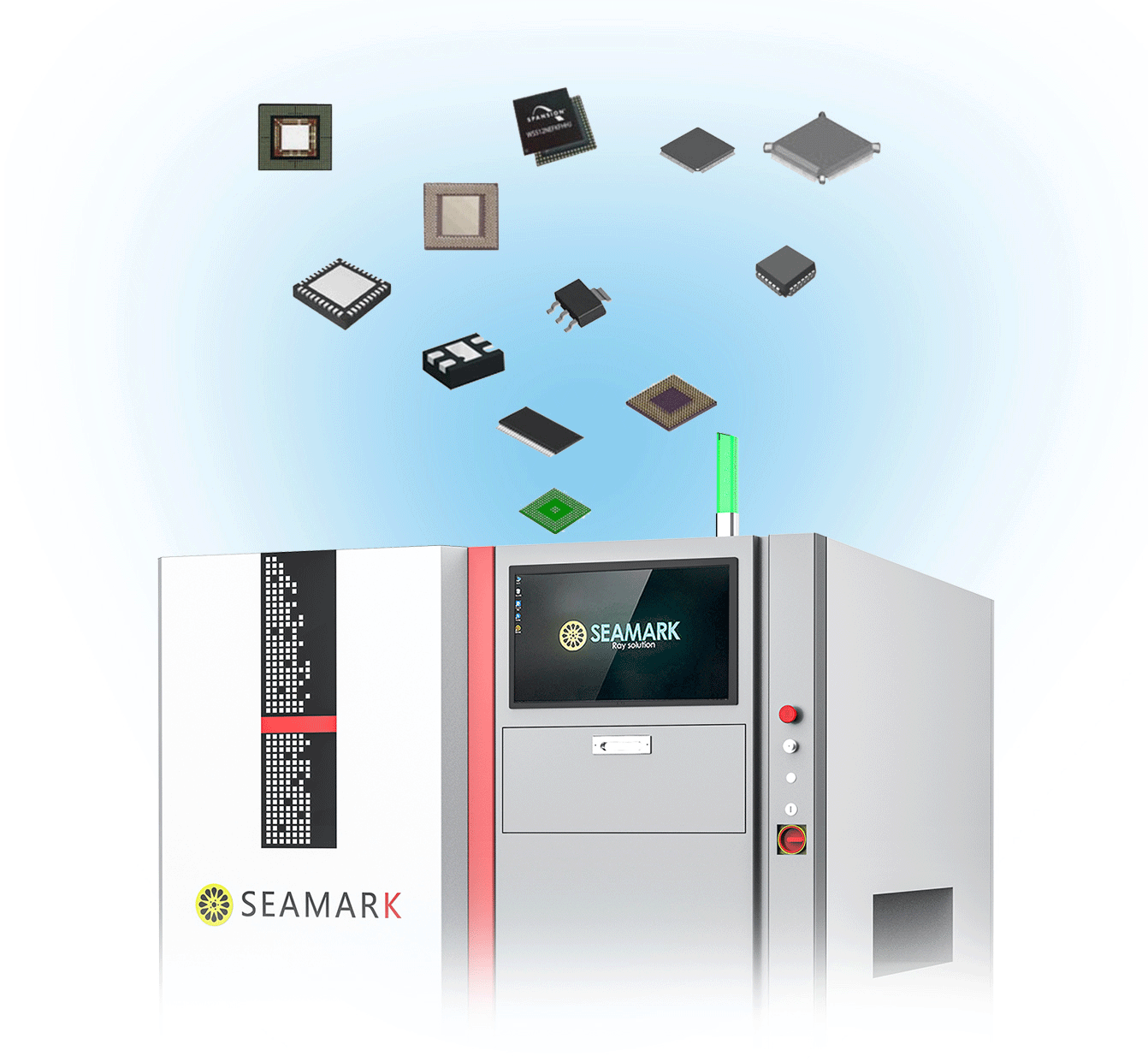

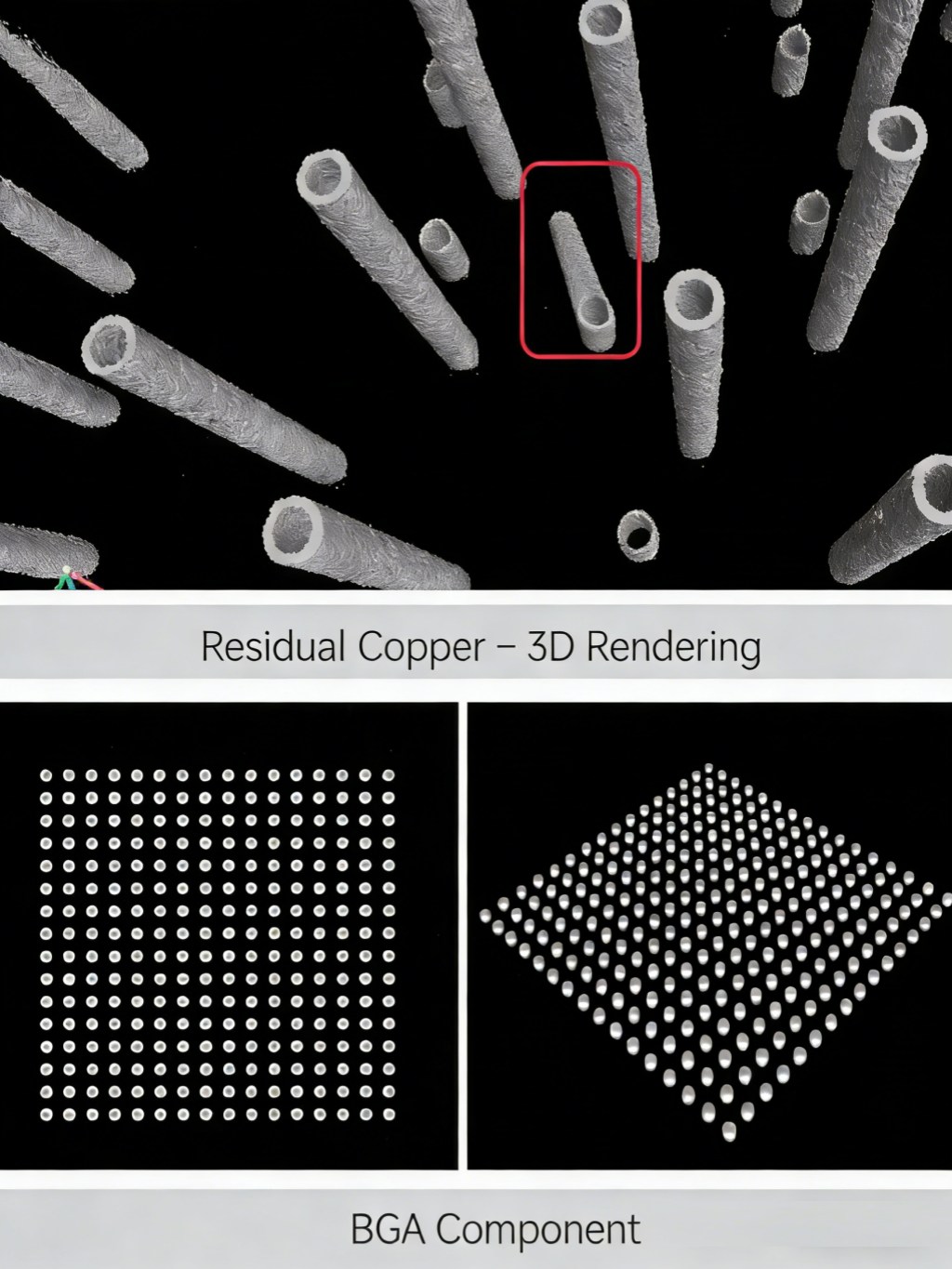

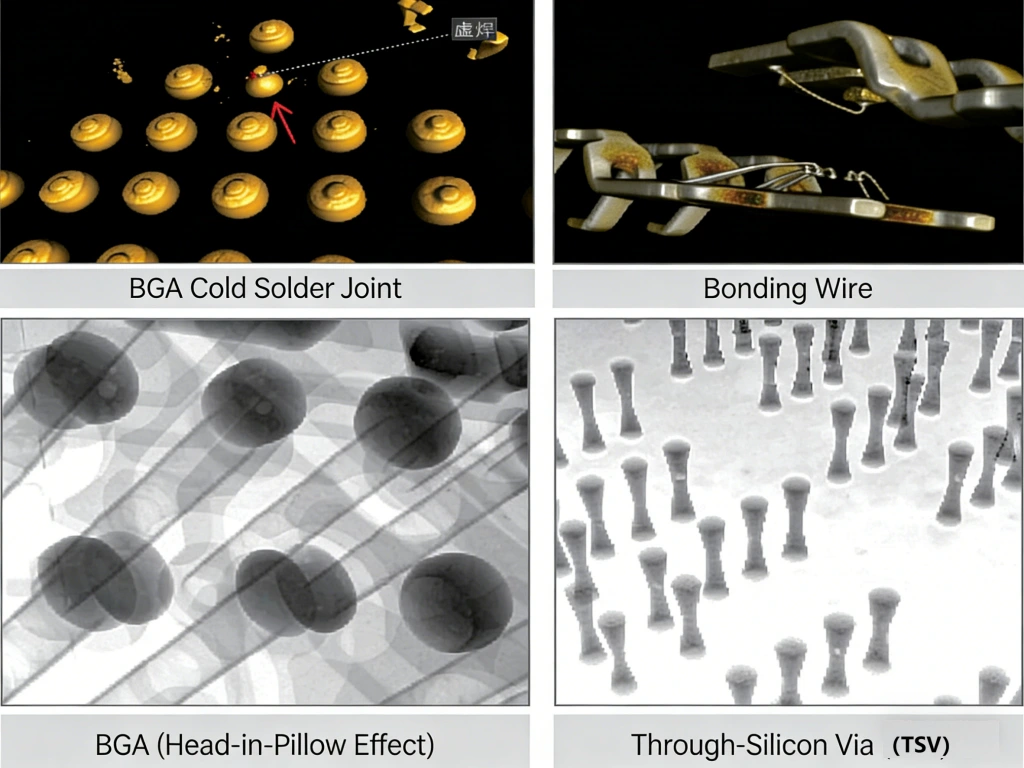

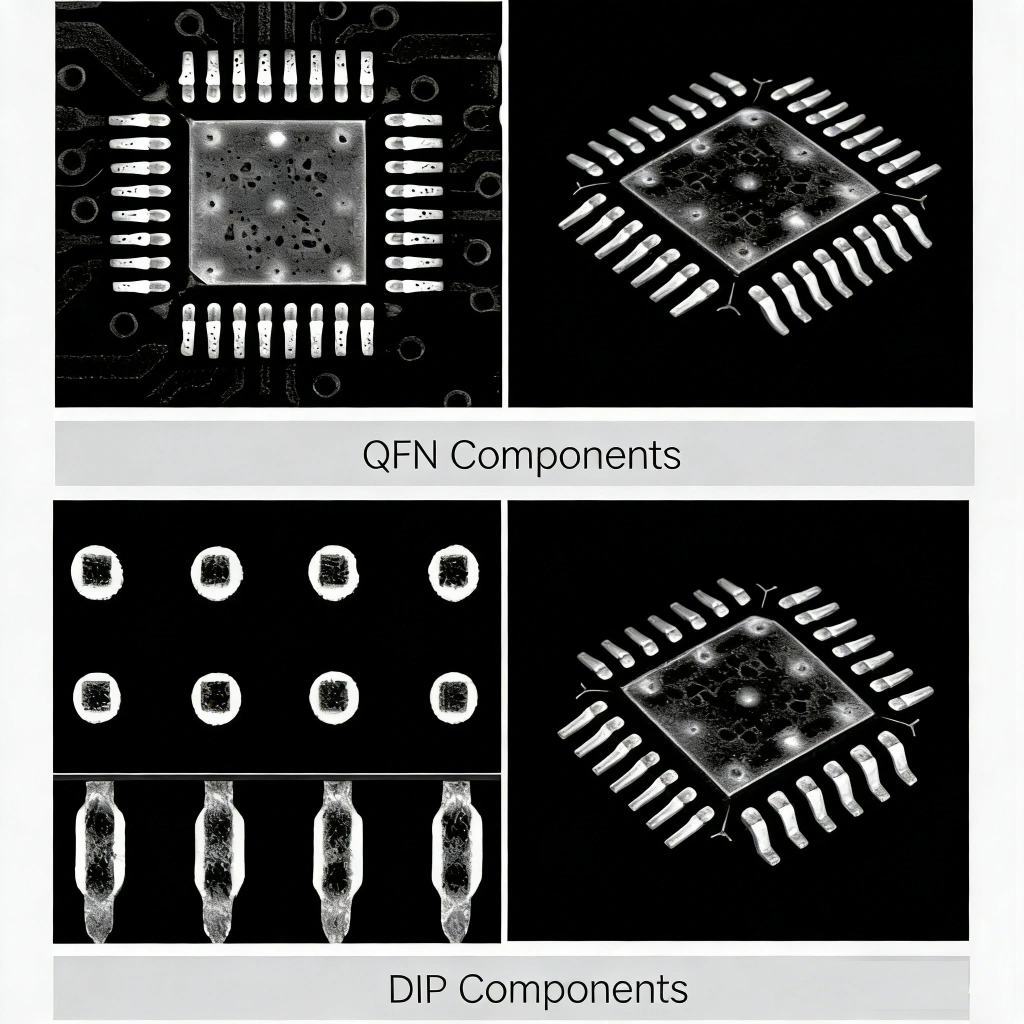

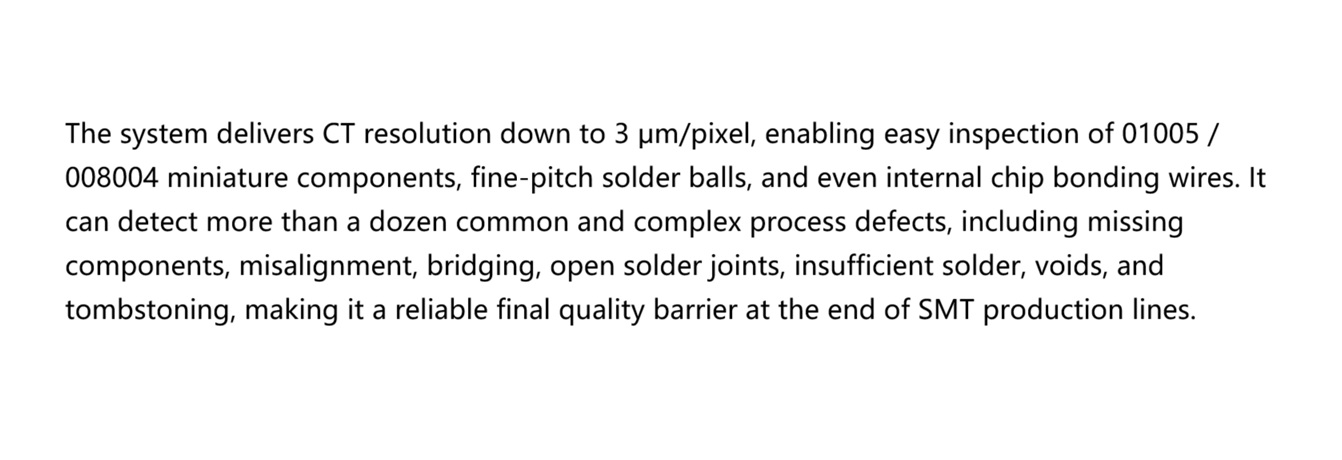

Equipped with innovative, self-developed intelligent inspection software, the system enables high-speed 3D inspection. It can inspect components such as BGA, POP, LGA, QFP, CSP, CHIP, QFN, DIP through-hole components, IGBT, and others. The system can detect defects including missing components, misalignment, solder bridging, open solder joints, insufficient solder, voids, and tombstone effects.

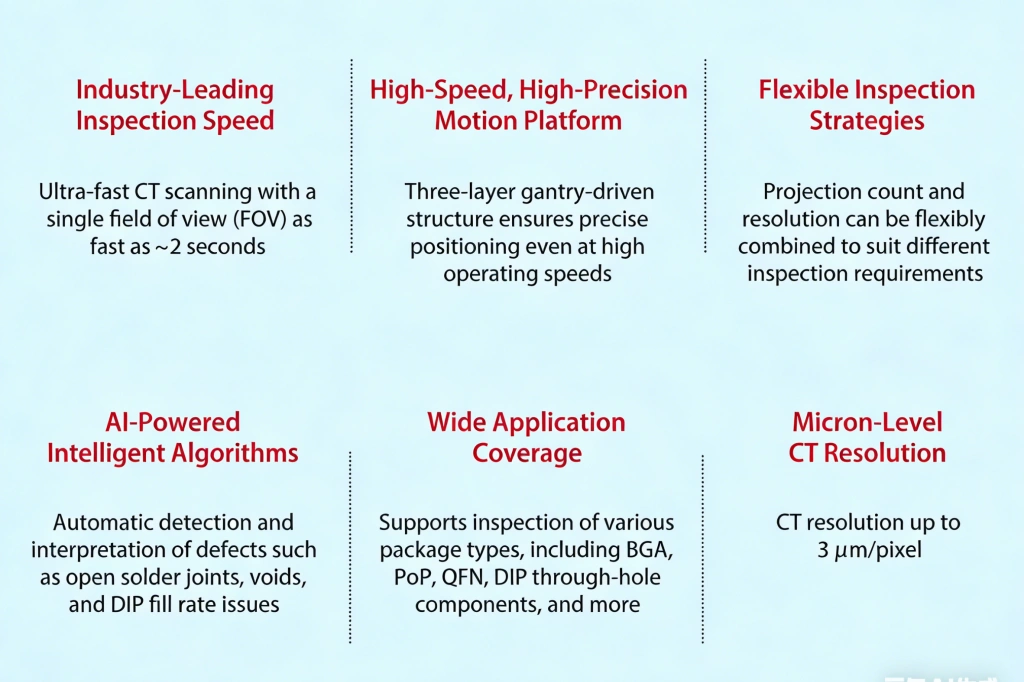

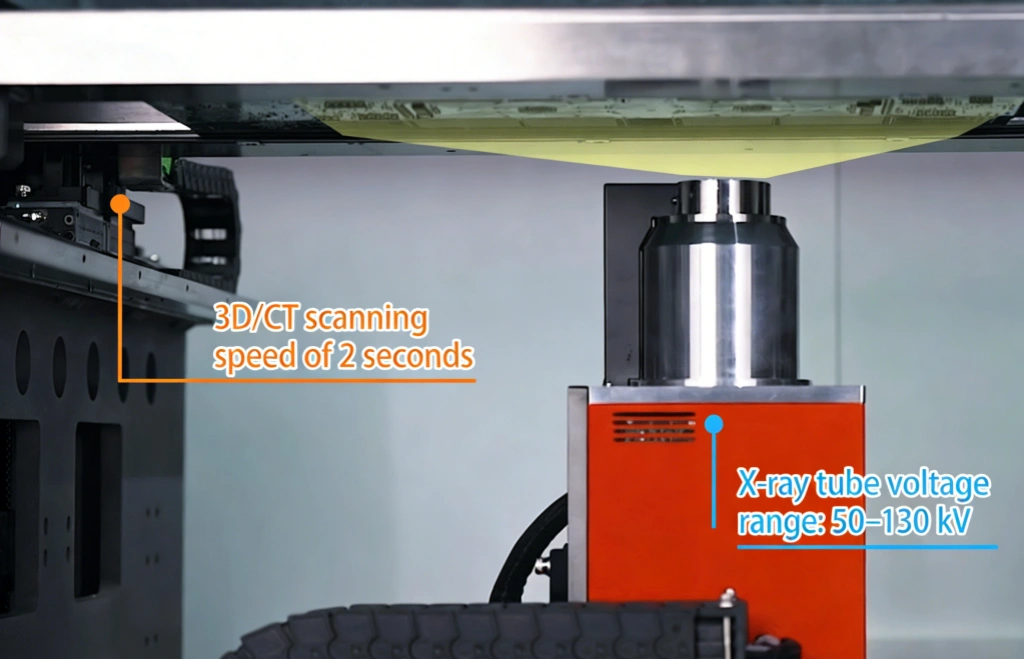

Unique 3D/CT reconstruction technology enables inspection at speeds as fast as < 2 s per FOV

Innovative in-house developed algorithms achieve high-precision detection of defects such as open solder joints, voids, and DIP fill rate issues

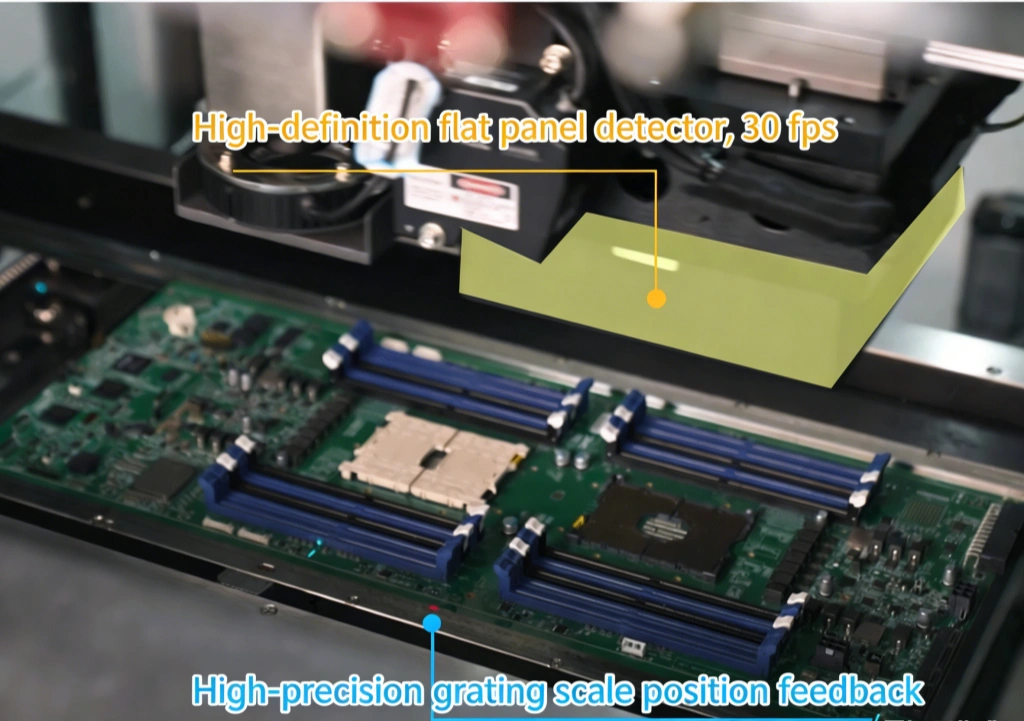

Equipped with a three-layer gantry structure driven by linear motors and grating scales, enabling high-speed CT scanning

Flexible combination of projection numbers and resolution to meet inspection requirements for various scenarios

| Model | AXI9000 | |

|---|---|---|

| X-Ray Tube | Type | Reflection-sealed micro-focus X-ray source (optional) |

| Voltage Range | 50-130KV | |

| Current Range | 0-500 μA | |

| Maximum Output Power | 65W | |

| Flat Panel Detector | Type | Flat panel detector (optional) |

| Pixel Matrix | 1536×1536 | |

| Field of View (FOV) | 154mm×154mm | |

| Resolution | 5.0Lp/mm | |

| mage Frame Rate (1×1) | 30fps | |

| A/D Conversion | 16bits | |

| Equipment Specifications | X-Ray Leakage | <0.5μSv/hr |

| Air Pressure | 0.45~0.65MPa | |

| Input Power | 220V 10A 50-60HZ | |

| Control System | Professional GPU imaging workstation | |

| Dimensions | L1630mm×W1950mm×H1600mm | |

| Net Weight | 4000KG | |

| PCB Inspection | PCB Size | 50×50 - 610×510mm |

| CT Resolution | 6–50 μm/pixel (3 μm optional) | |

| PCB Thickness | 0.5mm-10mm | |

| PCB Height | Top ≤ 50 mm, Bottom ≤ 40 mm |

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru