XL6500F is an inline precision micro-focus X-ray inspectiondevice designed for automotive FPC (Flexible Printed Circuit)boards, specifically for the automatic inspection and judgmentof nickel pads or designated components in automotiveapplications.

Fully automated inline inspection of soldered components (nickel pads) on thebottom of automotive FPC boards, accurately detecting defects such as soldervoids, insufficient solder, cold solder joints, and misalignment.

Simple template setup and easy operation, allowing for quick mold changes.

Fast programming with simple and user-friendly template editing for inspection.

Supports customized integration with MES(Manufacturing Execution System).

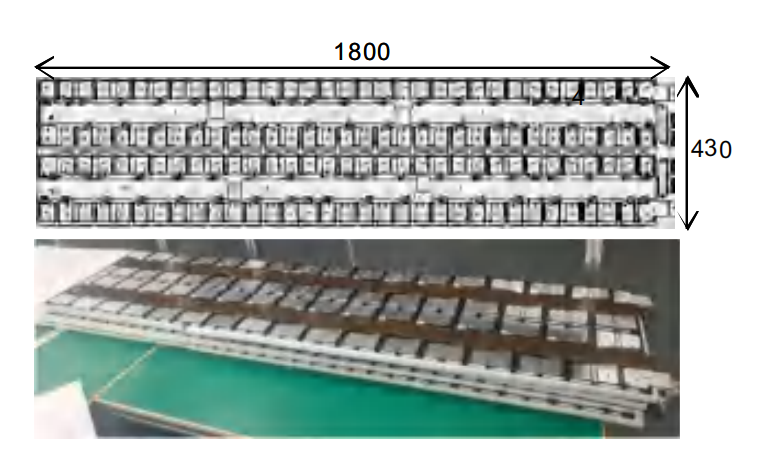

Conveyor system adopts a chain-type design, offering strong load-bearingcapacity.

User-friendly software interface with powerful system algorithms.)

Automatic barcode recognition and correlation of barcode information withinspection results.

NG (No Good) marking mechanism supports options like spray codes or laser marking.

Real-time monitoring of radiation levels with multiple safety protectionsfor operator safety.

Three-stage design, with flexible options for one-stage, two-stage, orthree-stage configurations to meet various site requirements.

Al-based intelligent inspection for precise Inspection of defects, with multi-pointsetup based on user product specifications.

Memory programming for automatic recording of inspection motion paths,ensuring accurate positioning and ease of repeat inspection.

All "OK" and "NG" images are processed in real time and saved online.

Supports uploading of inspection results in various formats to MES systems.

Wide adjustment range for conveyor rails, capable of handling FPC carriers up to500mm in width.

Chain-type conveyor design ensures strong load-bearing capacity.

The system uses 1.5-meter and 2-meter conveyor rails (optional), compatiblewith most product specifications on the market based on customerrequirements.

Automatic width adjustment for conveyor rails.

Pneumatic cylinders for stop-positioning to ensure standardized fixturealignment for different specifications.

Model | XL6500F | |

|---|---|---|

| X-Ray Tube | X-Ray Tube Type | Reflective sealed micro-focus X-ray source |

| Tube Voltage | 0-90KV | |

| Tube Current | 0-200μA | |

| Maximum Output Power | 8W | |

| Micro Focus Size | 10μm | |

| Flat Panel Detector | Flat Panel Type | Amorphous silicon flat panel detector |

| Pixel Matrix | 1536*1536 | |

| Field of View | 130mm*130mm | |

| Resolution | 5.8Lp/mm | |

| Image Frame Rate (1×1) | 20fps | |

| A/D Conversion | 16bits | |

| Equipment Specification | Equipment Specifications | 250-500mm |

Input Power | 220V 10A/110V 15A 50-60Hz | |

| Operation System | Industrial Computer Win10 64bits | |

| Net Weight | 4500KG | |

| Dimensions(1.5m Board) | L6200m*W1600*H2100mm | |

| Dimensions(2m Board) | L7700mm*W1600m*H2100mm | |

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru