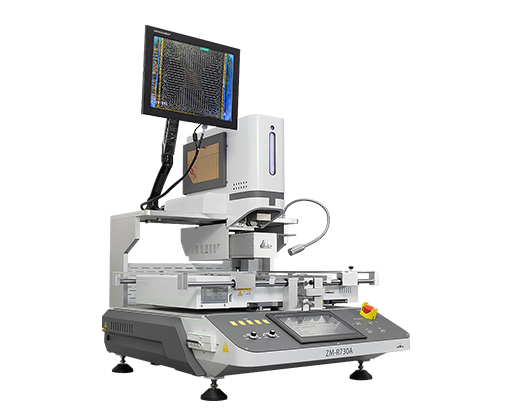

ZM-R730A large board BGA rework station is a kind of Semi-Automatic Soldering Machine. The machine has stable temperature control, a large HD touch screen, HD optical alignment and intelligent control as well as removable infrared temperature zone and other advantages. As one of the most reputable and professional BGA Rework Station suppliers, Zhuomao promises to produce the best products with good quality.

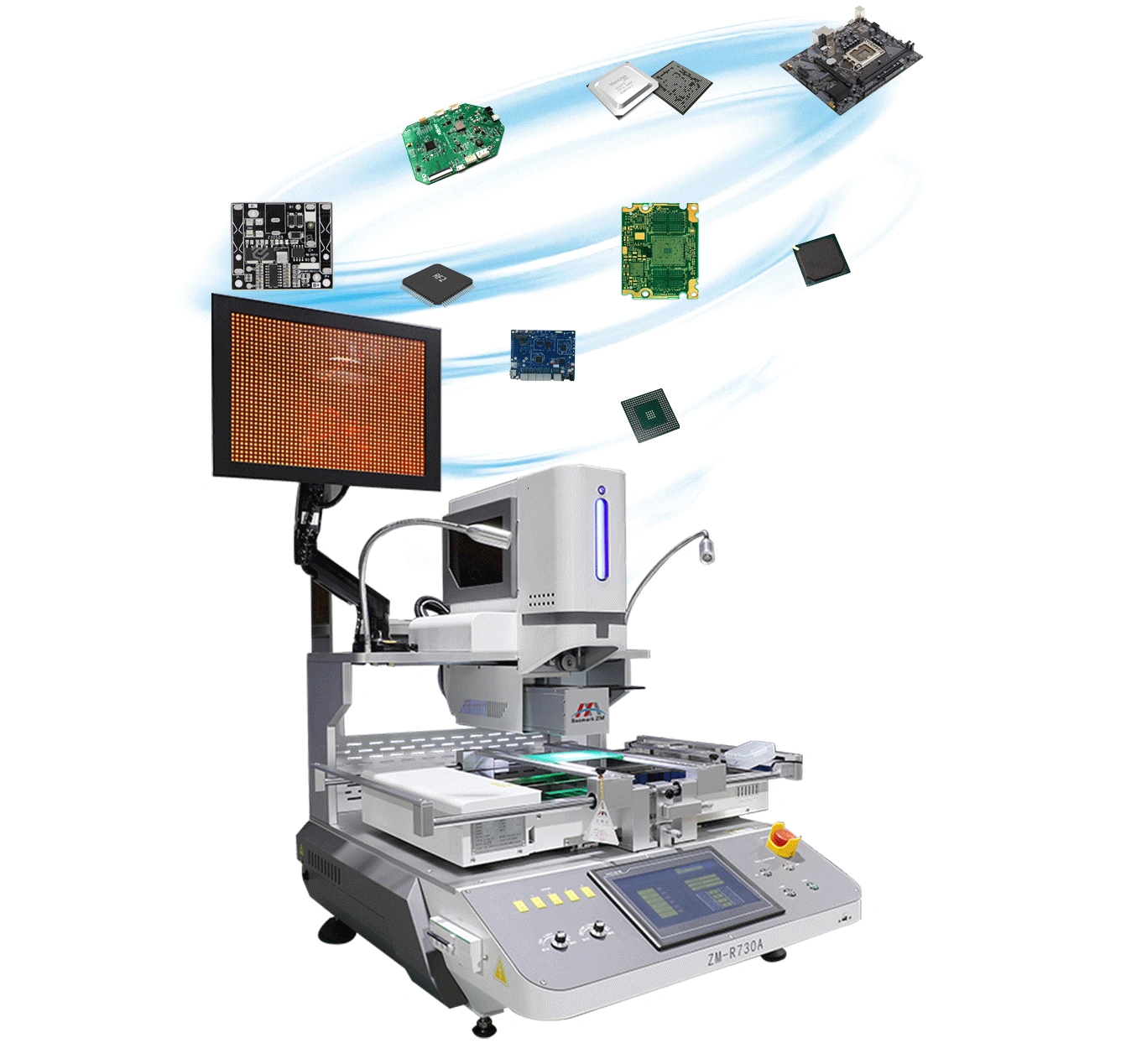

Three temperature zones independently control, heated by convection hot air, the height of the bottom temperature zone is adjustable, the top temperature zone has a built-in vacuum suction nozzle for chip adsorption, with negative pressure monitoring and pressure protection device.

Large HD touch screen operation with a variety of operation modes, real-time display, and edit temperature curve, each group of temperature curve can be set to 8 segments, can store 100 groups of temperature curve, can automatically analyze the curve, read through touch screen control.

The IR preheating zone is heated by a carbon fiber infrared tube and protected by a high-temperature resistant microcrystalline panel. It can move left and right to facilitate maintenance of large and irregular PCBA.

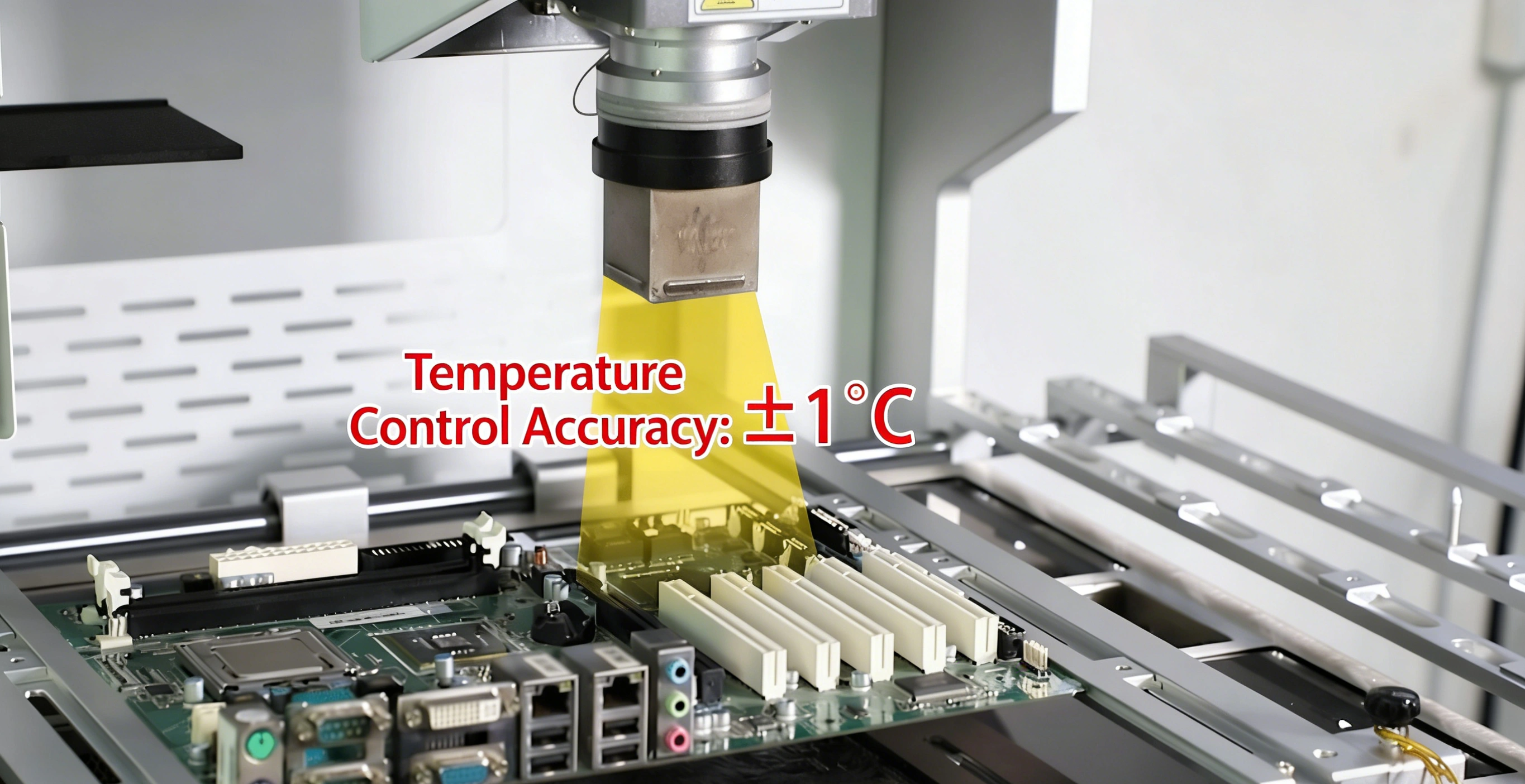

Equipped with automatic feeding device, using Panasonic PLC and high-precision temperature control module, high-precision K-type thermocouple, dynamic PID multi-loop closed-loop control selective reflow soldering process, the accuracy can reach ± 1 ℃. Over temperature protection alarm function, software encryption and foolproof function.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, reliable product quality, warm service. If you want to know the BGA repair machine and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

| Power Supply | AC380V±10% 50/60HZ |

| Power | 7.75KW(Max),Top heater(1.45KW) Bottom heater (1.2KW),IR Preheater (4.8KW), Other(0.3KW) |

| PCB Size | 632*520mm(Max); 6*6mm(Min) |

| BGA Chip Size | 80*80mm(Max); 3*3mm(Min) |

| IR Heater Size | 570*435mm |

| Temperature Sensor | 5 Pcs |

| Operation Method | 10" HD touch panel (1080P 16:9) |

| Control System | Panasonic PLC + Temperature control module |

| Display System | 15" HD industrial display ( 1080P 16:9) |

| Alignment System | 2 Million Pixel HD digital imaging system, automatic optical zoom with laser red-dot indicator |

| Vacuum Adsorption | Automatic |

| Alignment Accuracy | ±0.01mm |

| Temperature Control | K-type thermocouple closed-loop control with accuracy up to ±1℃ |

| Feeding Device | Yes |

| Positioning | V-groove with universal fixture |

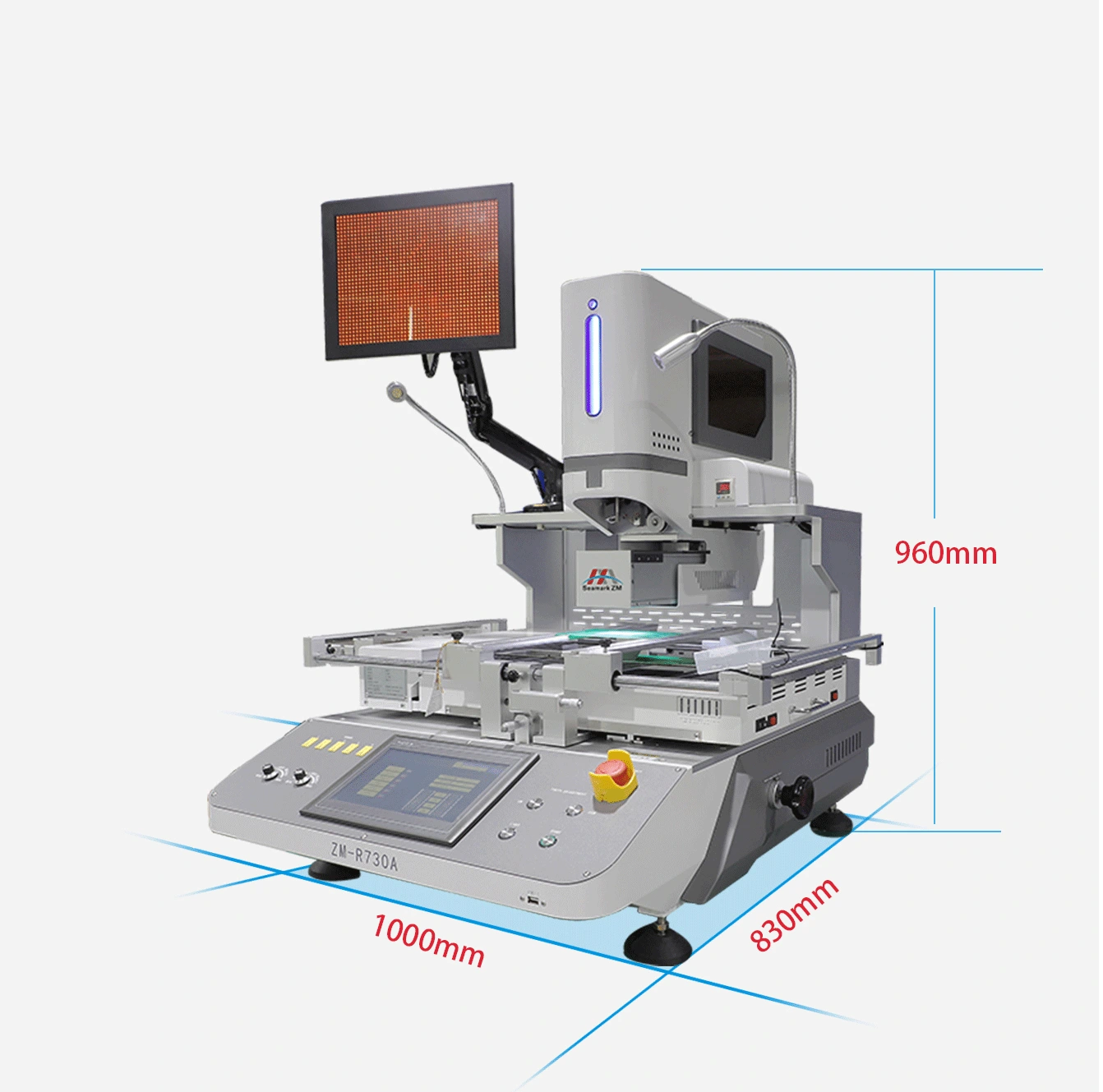

| Dimensions | L1000*W835*H960mm |

| Weight | 130.5KG |

The ZM-R730A is equipped with a 2-megapixel high-definition digital imaging system and an automatic optical zoom lens, achieving alignment accuracy of ±0.01 mm.

Even micro solder pads that are invisible to the naked eye can be automatically and precisely recognized and positioned, ensuring a high first-pass rework success rate.

The system adopts a high-precision K-type thermocouple–based dynamic PID multi-loop closed-loop control system.

Temperature is monitored in real time and continuously compared with the preset thermal profile, allowing instantaneous output adjustment to achieve temperature control accuracy of up to ±1 °C.

This delivers “laboratory-grade” repeatability and consistency for the rework process, while effectively protecting temperature-sensitive components.

The system features an extra-large 570 × 435 mm IR heating zone, fully covering most large-sized PCBs and delivering uniform and stable thermal radiation.It integrates an automatic board feeding mechanism and a vacuum suction system. With only a single setup, the equipment automatically completes PCB transfer and positioning, significantly improving production efficiency. This ensures consistent results for every rework operation and effectively reduces human error.

With a movable infrared heating zone, V-groove, and universal fixtures, along with a PCB support size of 632×520 mm and a chip handling capability of 3×3 mm, the Seamark R730A offers outstanding process flexibility. From large industrial control boards to compact consumer electronics motherboards, a single unit can handle them all, achieving true “multi-purpose functionality.”

The equipment achieves not just heating, but a complete selective reflow soldering process based on closed-loop control. It ensures that the entire workflow—from alignment to heating—is under precise monitoring and feedback, making the soldering quality of rework points virtually equivalent to the original SMT assembly level.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru