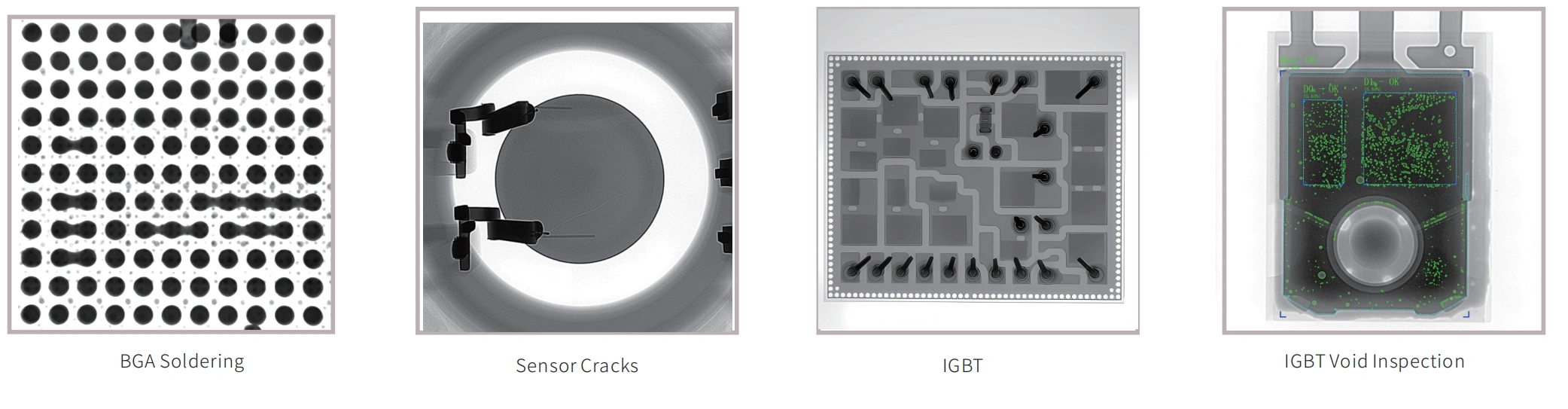

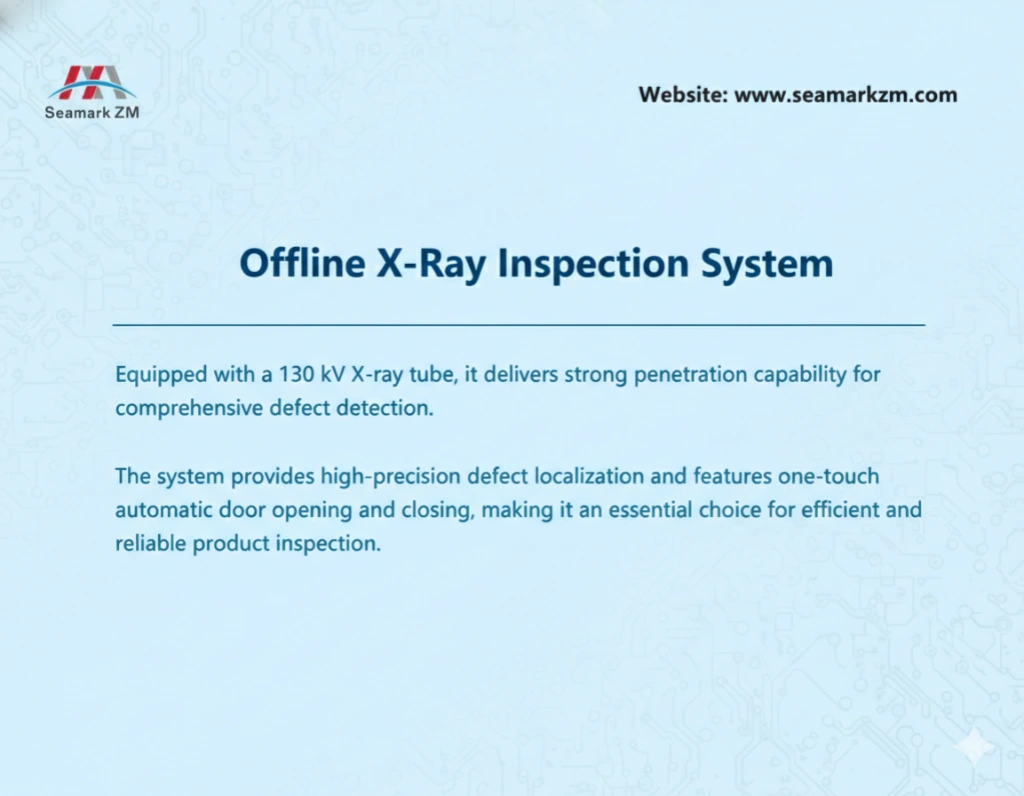

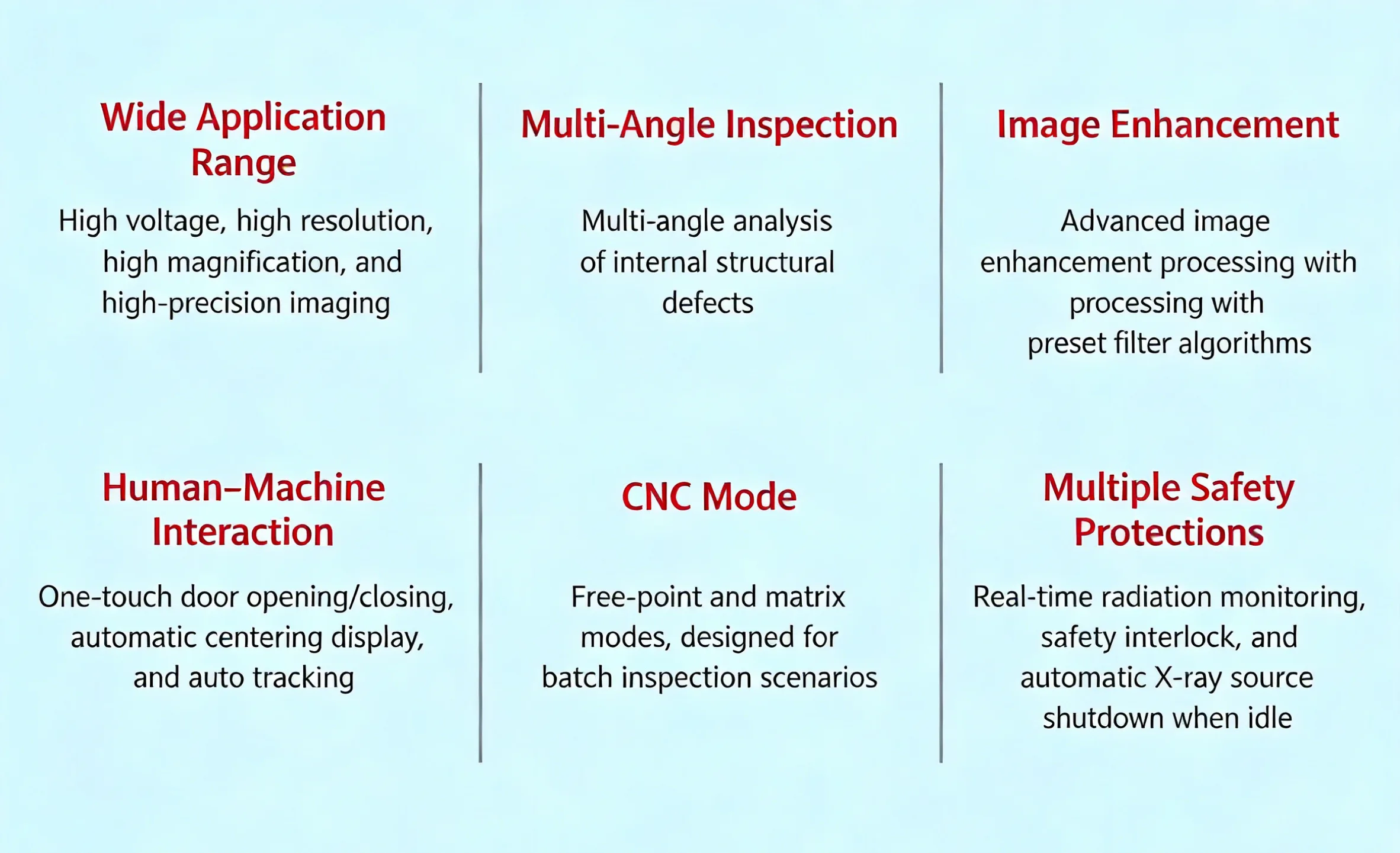

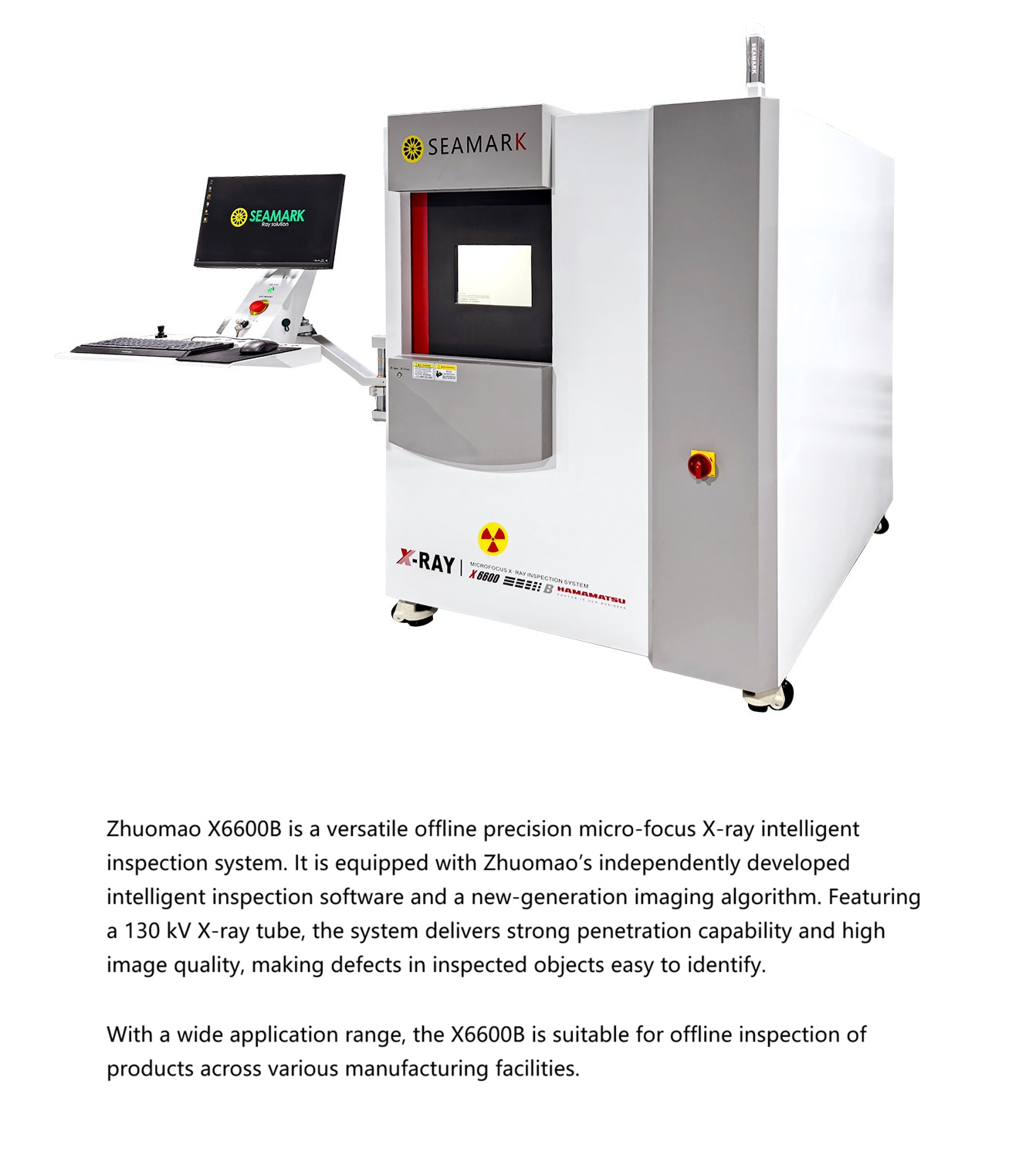

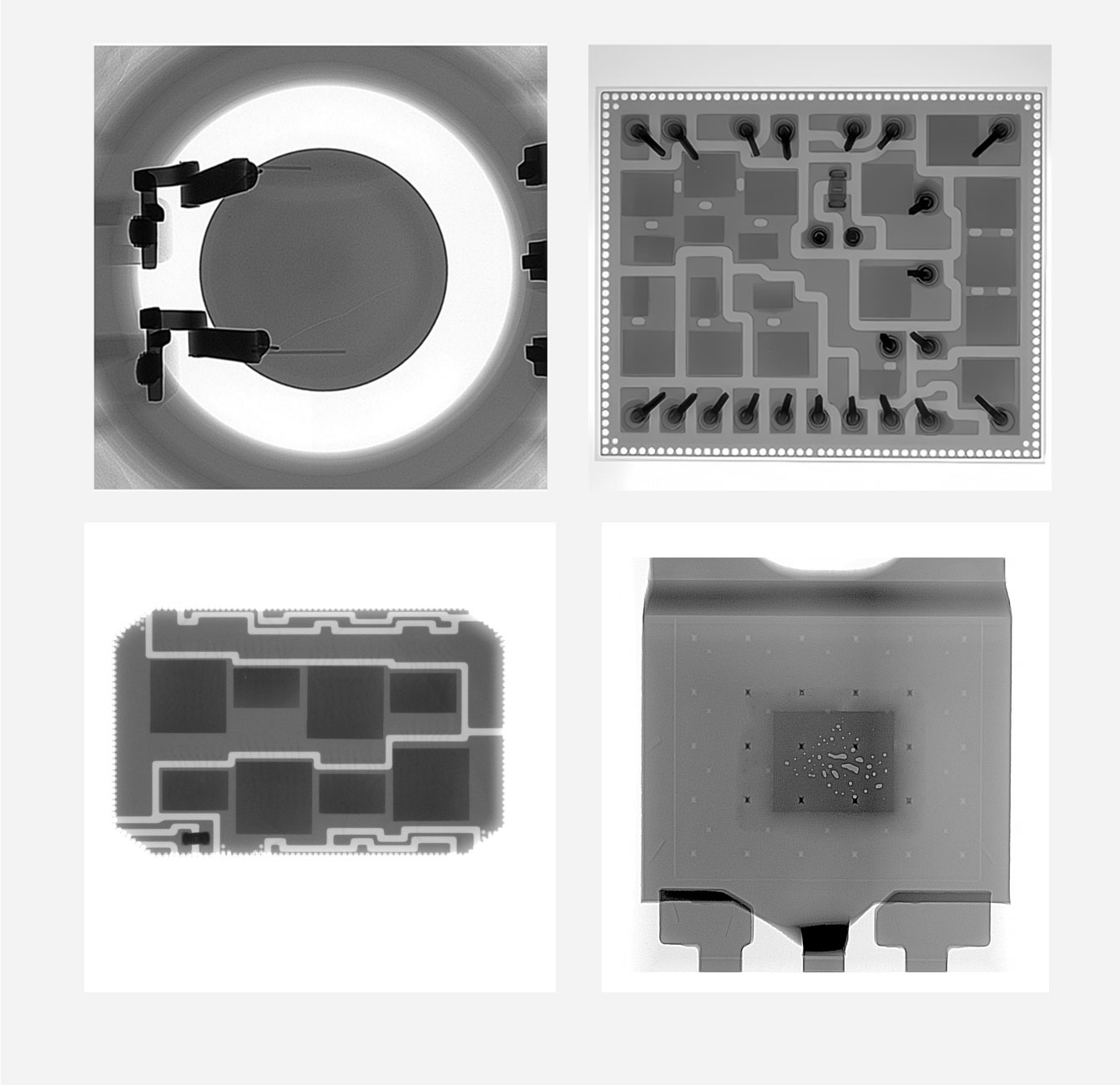

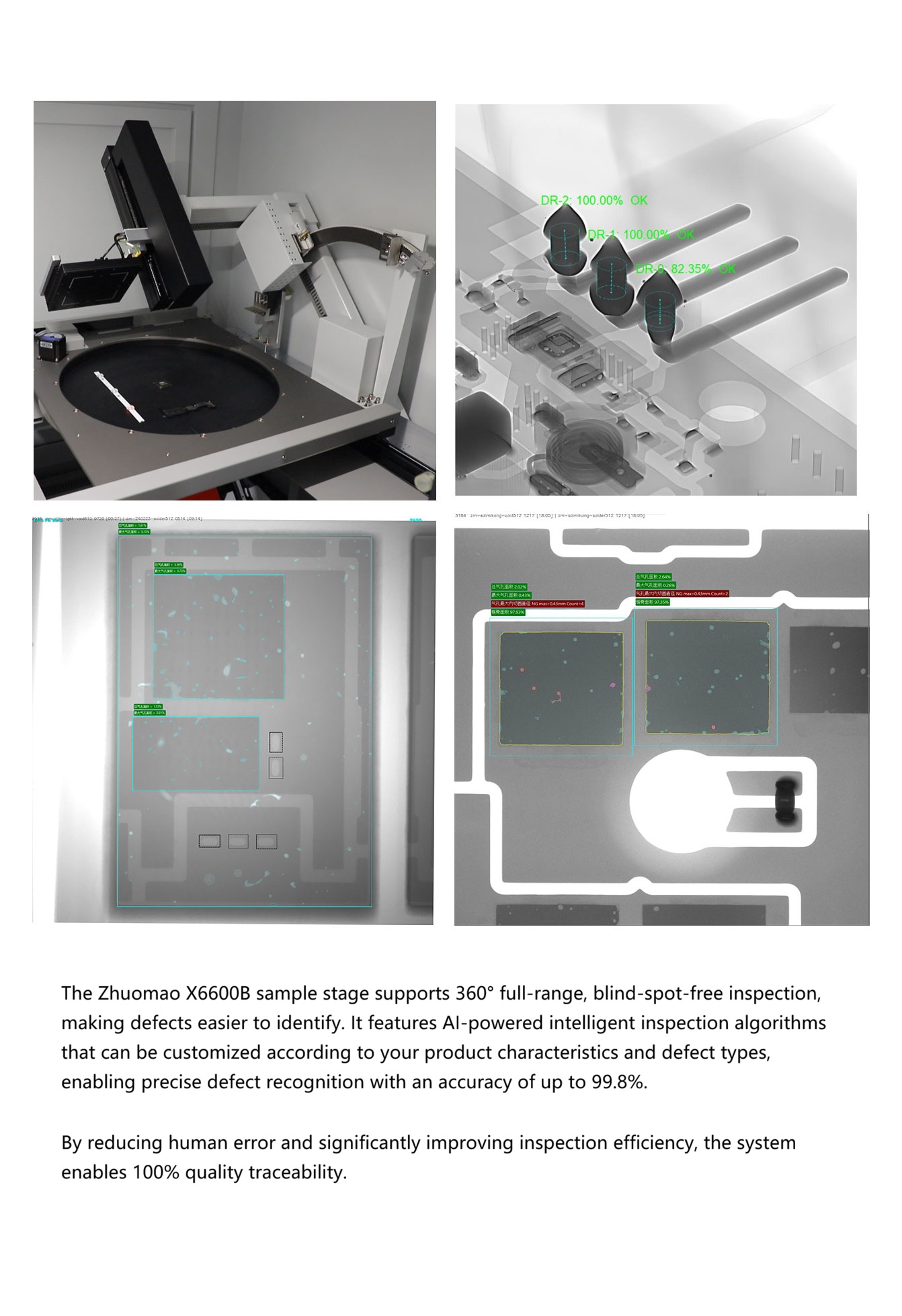

X6600B is a 6-axis universal offline precision micro-focus X-ray inspection equipment. It has the characteristics of high magnification, multi-angle,and large-area inspection platform. At the same time, it has one-button door opening and closing,and real-time monitoring of radiation conditions around the equipment to ensure the safety of the environment and operators. Ideal for detecting BGA voids, Head-in-Pillow (HIP), QFN solder bridging, and IGBT wire bonding defects.

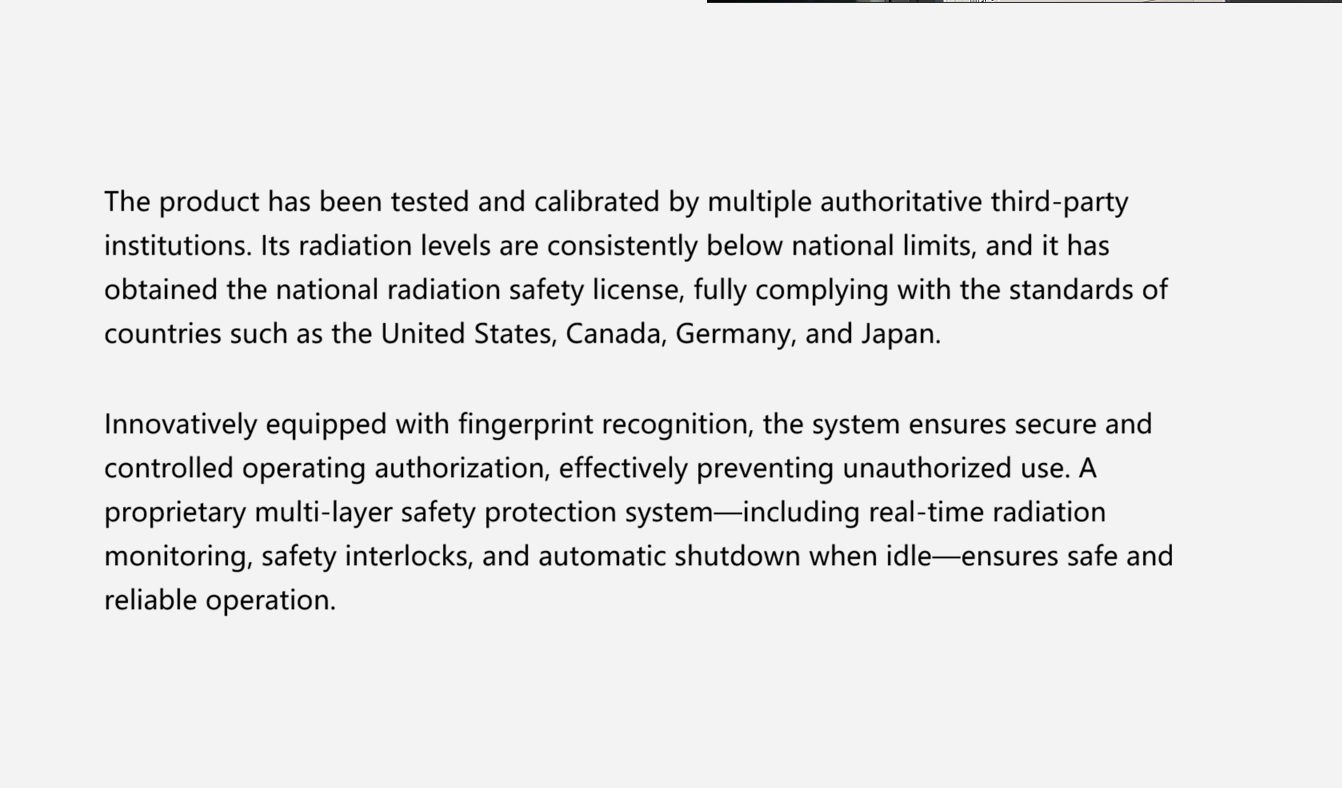

Fingerprint authentication authorizes designated personnel to operate the system

The X and Y axes of the stage adopt high-precision ball screw drive systems, ensuring inspection accuracy

When standard vertical inspection cannot meet requirements, the T-axis tilt inspection function can be used to achieve more comprehensive inspection coverage

Real-time radiation level monitoring with multiple safeguards to ensure operator safety

| Model | X6600B | |

|---|---|---|

| X-ray Tube | Tube Type | Reflection sealed microfocus X-ray source |

| Tube Voltage Range | 40-130KV | |

| Tube Current Range | 10-300μA | |

| Maximum Output Power | 39W | |

| Microfocus Spot Size | 5 μm (at 4 W) – 40 μm | |

| Flat Panel Detector | Flat Panel Type | Amorphous Silicon Flat Panel Detector |

| Pixel Matrix | 1536×1536 | |

| Field of View | 130mm×130mm | |

| Resolution | 5.5Lp/mm | |

| Image Frame Rate (1×1) | 20fps | |

| A/D Conversion | 16bits | |

| System Specifications | Dimensions | L1380xW1425xH1951mm |

| Input Power | 220V 10A 50-60HZ | |

| Maximum Sample Size | 620mm×620mm | |

| Operation System | Industrial PC, Windows 10 (64-bit) | |

| Net Weight | 1800KG |

A: The X6600B accommodates a large inspection area with a maximum sample size of 620mm x 620mm. It features a 130mm x 130mm Field of View (FOV) and supports multi-angle inspection for various PCBA sizes.

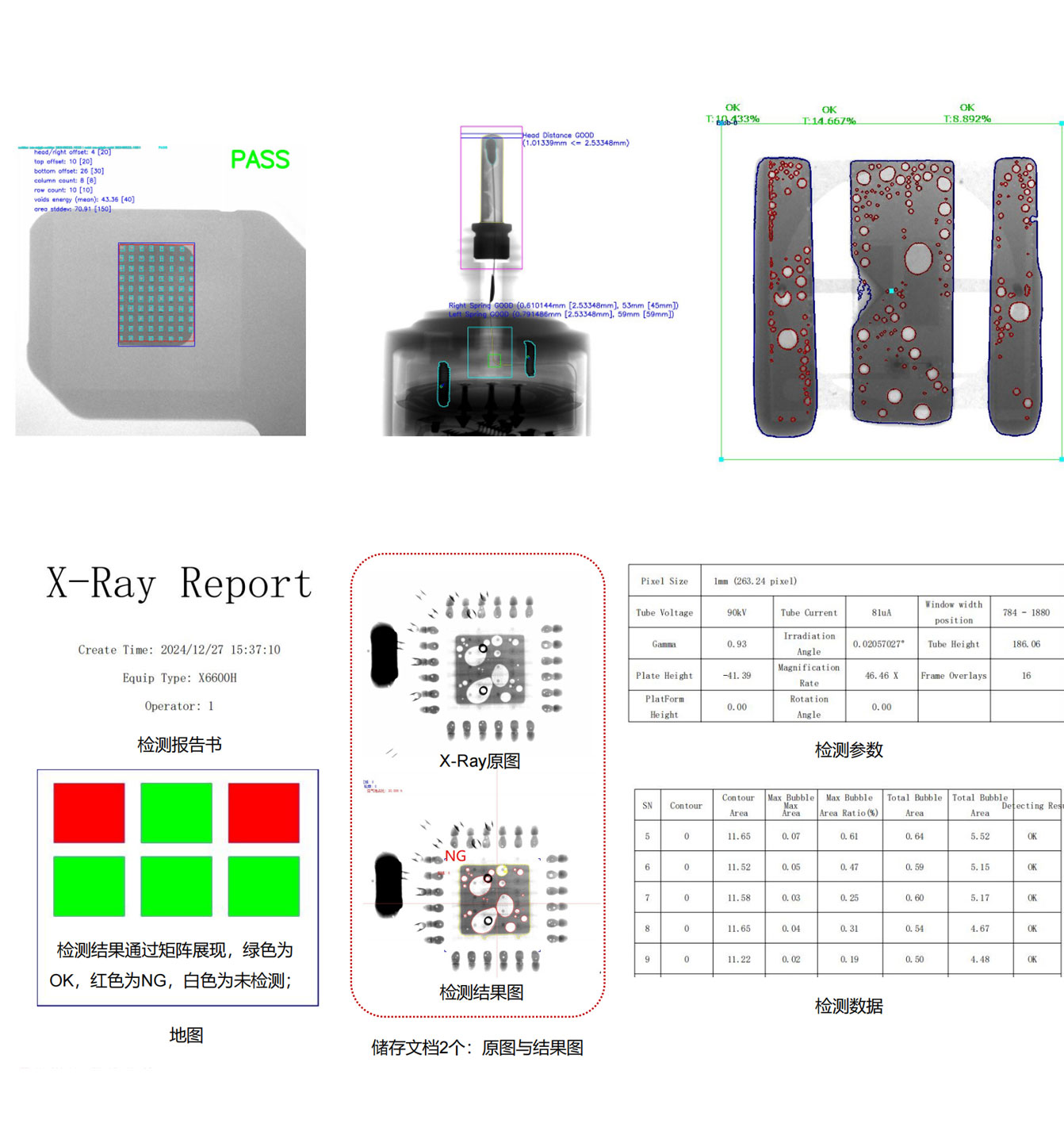

A: Yes, the X6600B is specifically designed for high-precision inspection of IGBT modules, BGA, CSP, QFN, and LED components. It effectively detects defects such as BGA voids, cold solder joints, head-in-pillow (HIP), and wire bonding breaks.

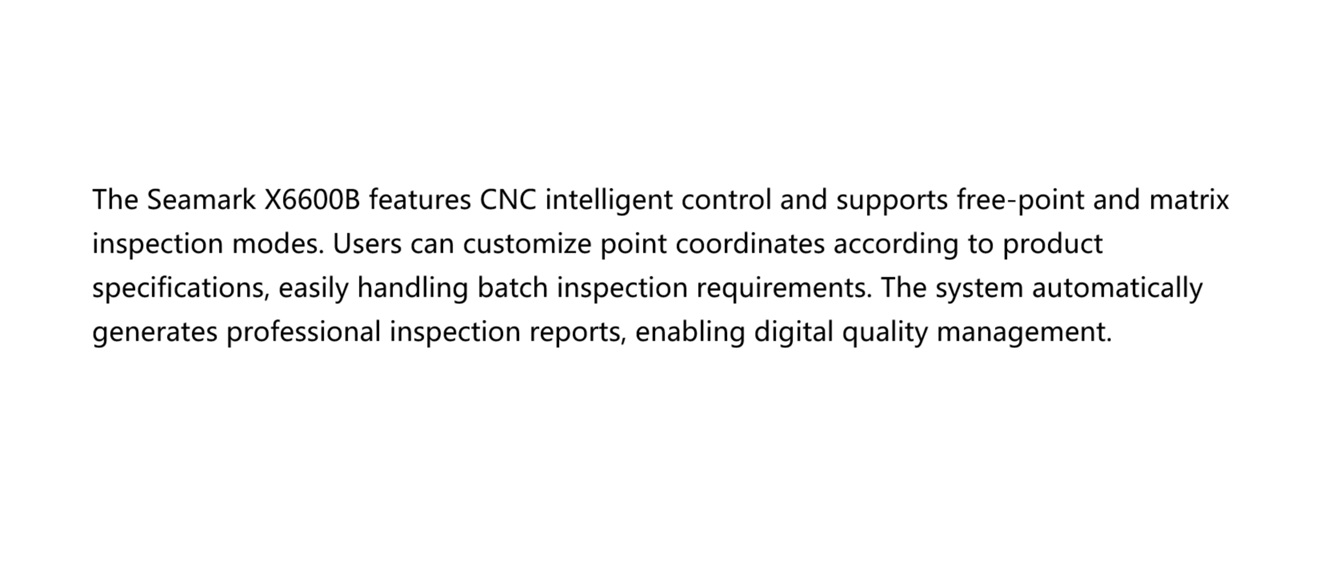

A: Yes, the machine features a CNC programming mode. This allows operators to set multi-point coordinate arrays for automatic batch inspection, significantly improving efficiency for mass production lines.

A: The X6600B is equipped with a micro-focus X-ray tube with a spot size as small as 5μm (at 4W) and a flat panel detector resolution of 5.8Lp/mm, ensuring clear imaging of minute defects.

A: Yes, the intelligent inspection software includes an Automatic Void Ratio Calculation function. It can automatically identify BGA soldering balls and calculate the void percentage, generating a detailed quality report.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru