"Industry 4.0" has become one of the hottest terms in the manufacturing industry in recent years. As one of the topics, Intelligent SMT Automated Assembly has naturally received widespread attention in the electronics manufacturing industry. Seamark Zhuomao Technology is a manufacturer of robust, high-performance Industry 4.0 compliant SMT equipment.

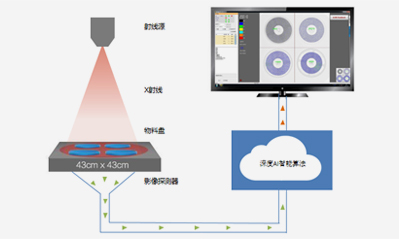

We manufacture and supply: BGA rework station including manual, semi-automatic, and fully automatic BGA repair station including a solution for PCBA repair. We also supply microfocus X-ray inspection machines, both off-line and in-line, and including a 3D/CT X-ray inspection. Our inventory management solutions encompass both on-line & off-line X-ray SMD reel counter and SMD smart storage systems, such as smart storage racks, smart storage towers, and smart storage warehouses. This diversified product range with reasonable pricing and global technical support enables us to supply a growing global SMT/EMS customer base with our advanced systems and solutions. We always focus on providing creative and affordable equipment & solutions for the SMT field and EMS companies.

All machines are designed easy to operate and maintain, save maintenance time and cost.

Quality priority, strict inspection process to make sure each machine arrives at good condition.

A strong after-sales service team which is made of 20 engineers, can provide quick and professional installation, maintenance and technical support, etc.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr