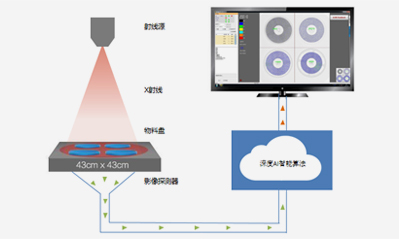

It is equipped with a multi-angle RGBW lighting system, a four-channel low-angle 3D projection system, high-resolution high-speed cameras, and telecentric lenses. The system is standardly configured with a Y-axis gantry driven by dual motors.

The system adopts 2D + 3D hybrid inspection, acquiring three-dimensional data of components and solder joints through 3D imaging, combined with 2D planar information to achieve comprehensive inspection. It is particularly suitable for high-density and miniaturized components.

The S3030 enables inline 3D automatic optical inspection, capable of detecting SMT PCB defects such as missing components, misalignment, polarity errors, insufficient height, side standing, tombstoning, so

Supports offline programming; program creation and debugging do not affect production line operation

12-megapixel high-resolution industrial camera (21-megapixel optional)

Standard Z-axis module, supporting large-range PCB warpage compensation

Multi-angle lighting combined with a high-resolution camera and telecentric lens significantly improves inspection performance

| Model | S3030 | |

|---|---|---|

| Vision System | Imaging | 12MP industrial camera (21MP optional) |

| Resolution | 5μm/10μm/15μm | |

| Inspection Speed | 6.7c㎡/s 26.7c㎡/s 60c㎡/s | |

| Illumination | RGBW LED | |

| Hardware | Power Supply | 200V-230V AC 50/60Hz |

| Power Consumption | 2.2KW | |

| Air Pressure | 0.4-0.6MPa | |

| Weight | 1300KG | |

| Machine Dimensions | 1100mm(L)*1350mm(W)*1630mm(H) | |

| Inspection Specifications | PCB Size | 510*460mm |

| PCB Thickness | 0.4-6mm | |

| PCB Edge Clearance | 3mm | |

| Top & Bottom Clearance | 45mm | |

| Conveyor Height | 900±50mm | |

| Measurement Height | Components up to 30mm in height | |

| Optional Functions | AI Inspection | Detectable defect types include pre-reflow solder balls, gold surface scratches, gold surface contamination, solder adhesion, solder beads, and foreign objects |

| Auxiliary Functions | Remote centralized review;Barcode reading;OCR recognition | |

| Inspection Items | Defect Detection | Missing components, misalignment, polarity reversal, insufficient height, side standing, tombstoning, solder joint defects, solder beads, oxidation contamination, foreign objects, scratches, etc. |

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr