This equipment is suitable for the repair of defective semiconductor chip packaging processes. It utilizes a single-point solder ball placement laser welding system, with human-machine control and an intelligent motion system. It supports multiple product formula storage, enabling simple and quick program switching.

The standard SMT conveyor-type loading and unloading system, along with an adjustable anti-static synchronous belt component, can be connected to upstream and downstream process equipment on the production line. The system has strong overall compatibility and is compatible with BGA industry-standard trays.

The non-contact single-point solder removal head, assisted by a high-precision laser displacement sensor for height measurement and a precise gravity sensor, effectively targets single-band defects in the product.

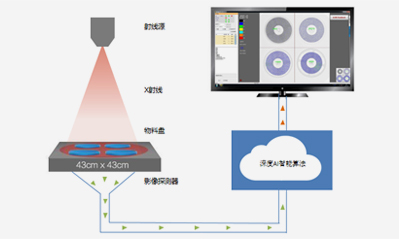

Four independent dipping arrays transfer flux from the flux supply system to the required ball placement welding positions. Four independent nozzles place solder balls at the welding positions, and laser welding is used to solidify the joints.

Equipped with three CCD vision systems, using self-developed control software to detect materials at the holes on the tray and precisely handle loading and unloading. AOI inspection is performed to accurately locate defects on the product, and ball placement nozzles are automatically calibrated after the production line changeover.

The system includes four independent preheating platforms, each equipped with a heating and temperature control system. The solder removal and ball placement of the BGA are both performed on the preheating platforms. Both the preheating platform and the solder removal head use closed-loop temperature control, ensuring stable and accurate overall temperature regulation.

| Category | ASE2500L | Specifications |

| Equipment Performance Parameters | Total Power | 5KW |

| Compatible BGA Chip Size | 27x27mm (Max); 3x3mm (Min) | |

| Tray Size | 323x136x8mm (Standard Industry Tray) | |

| Preheating Platform Temperature | ≤200°C (Adjustable) | |

| De-soldering Head Heater Temperature | ≤600°C (Adjustable) | |

| De-soldering Residue | ≤15% | |

| De-soldering Nozzle | Φ0.2-Φ1, replaceable | |

| Solder Ball Size | 0.2-0.76mm | |

| Ball Placement Accuracy | Deviation < 1/3 of ball diameter | |

| Ball Placement Nozzle | Φ0.15-Φ0.6, replaceable | |

| Production Yield | Above 95% | |

| Changeover Time | 30 minutes | |

| Ball Placement Nozzle Calibration | CCD + Tooling Sensor Calibration | |

| Dimensions | L1420xW1280xH1850mm | |

| Machine Weight | 1200KG |

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr