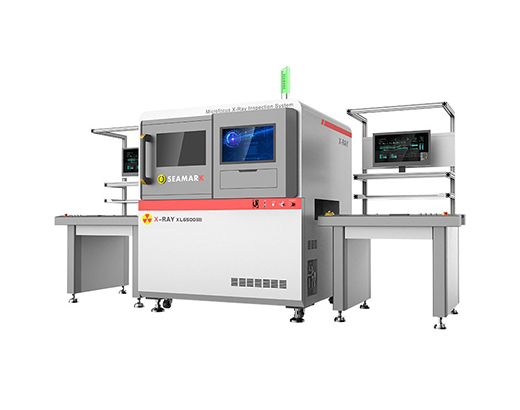

Microfocus X-ray inspection is widely used in the LED/automobile/aerospace/EMS ETC field and become a necessity for modern PCBA inspection. As a professional X-ray inspection machine manufacturer, Seamark Zhuomao provides SMT BGA X-Ray inspection machines that have the characteristics of high performance, cost-effectiveness, long lifespan, user-friendly software, simple maintenance, high definition inspection image with special tilt make our X-Ray AOI inspection equipment system can meet different category products inspection needs.

Besides standard X-Ray PCB inspection machines, Seamark ZM also provides and customized solutions to meet your special inspection requirements. As a professional BGA X-Ray inspection machine manufacturer in China, we have the valued BGA inspection system and various AXI X-ray inspection machines for sale. And our price of an X-Ray PCB inspection machine is fairly reasonable. Welcome to order.

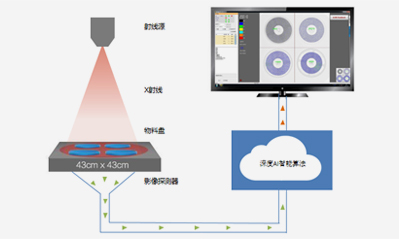

Automatic X-ray inspection (Axi) is a technology similar to the principle of automatic optical inspection (AOI). Electronics AXI X-ray Machine uses X-rays as a light source to automatically check the features of objects, which are usually hidden in the view. The X-ray Inspection Equipment usually can be used to check the PCB board.

As a famous X-ray Inspection Machine Manufacturer in China, Seamark ZM provides 4 categories of products and services, including the BGA Repair Station, 2.5D and 3D X-Ray inspection machine, inline and offline X-Ray reel counter/X Ray Inspection System, and smart storage system.

Yes, welcome to send us samples to test. Few batches of sample repairing and testing are free of charge. Contact us now.

We have CE and FDA. Our X-ray machine radiation leakage is less than 1μSv/h when it works, meet the international safety standard. Please feel confident when you use our PCB X-ray Machine.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr