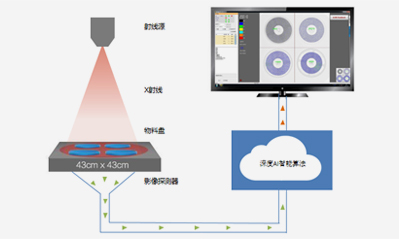

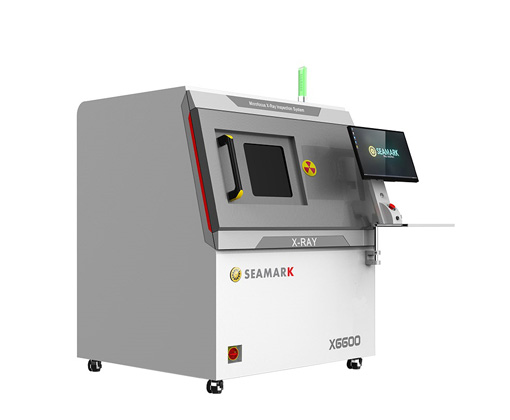

X6600 is a cost-effective general-purpose offline precision microfocus X-Ray inspection equipment. It is suitable for the inspection of various factory offline products. This AXI inspection machine has the characteristics of high magnification, multi-angle inspection, and a large-area inspection platform.

Meet the needs of the general industrial X-ray machine and have a wide range of applications.

A high-resolution design can obtain the best image in a very short time.

Infrared automatic navigation and positioning, quickly select the shooting location.

CNC detection mode, fast automatic detection for multi-point array.

Oblique multi-angle inspection makes it easier to detect sample defects.

Software operation developed by Seamark is simple and easy to use, low operating cost.

The X-ray tube and FDP can be rotated at the same time (0-60°), making the detection image more clear and intuitive.

As a professional x-ray inspection machine manufacturer in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable quality, good service. If you want to know the exact industrial x-ray machine price and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

| X-Ray Tube Source Specification | |

| Type | Sealed Micro-Focus X-Ray Tube |

| Voltage | 90 KV/130KV |

| Operating Voltage Range | 40-90KV/130KV |

| Operating Current Range | 10-200 μA/300μA |

| Max Output Power | 8 W/39W |

| Micro Focus Spot Size | 5-15μm |

| Flat Panel Detector Specification | |

| Type | TFT Industrial Dynamic FPD |

| Pixel Matrix | 1536×1536 |

| Field of View | 130mm×130mm |

| Resolution | 5.8Lp/mm |

| Frame(1×1) | 20fps |

| A/D Conversion Bit | 16bits |

| Dimensions | L1360mm×W1240mm×H1700mm |

| Input Power | 220V 10A/110V 15A 50-60HZ |

| Max Sample Size | 540 mm×440mm |

| Control System | Industrial PC WIN7/ WIN10 64bits |

| Net Weight | Approx 1170KG |

| Radiation | <1μSv/h |

| Max Tilt Angle | 65 degree |

Electronics Industry: Ideal for inspecting solder joints, PCBs, and semiconductors. Its high magnification and multi-angle inspection detect small defects like voids and cracks.

Automotive Industry: Ensures the quality of critical parts like sensors and battery cells. Its large platform supports larger items in high-volume production.

Aerospace Industry: Vital for inspecting complex components like circuit assemblies, ensuring reliability and safety by detecting internal flaws.

Medical Devices: Perfect for precision inspections of implants, catheters, and pacemakers, meeting strict safety standards.

Energy Sector: Provides high-resolution imaging to detect defects in components like insulators, transformers, and solar cells.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr